马辉

+

- 电子邮箱:

- 职务:东北大学教授、博士生导师

- 学历:博士研究生毕业

- 办公地点:机械实验楼305

- 联系方式:mahui_2007@163.com QQ: 13766590

- 学位:博士

- 毕业院校:东北大学

- 所属院系:机械工程与自动化学院

- 学科:

机械设计及理论

- 邮箱:

研究领域

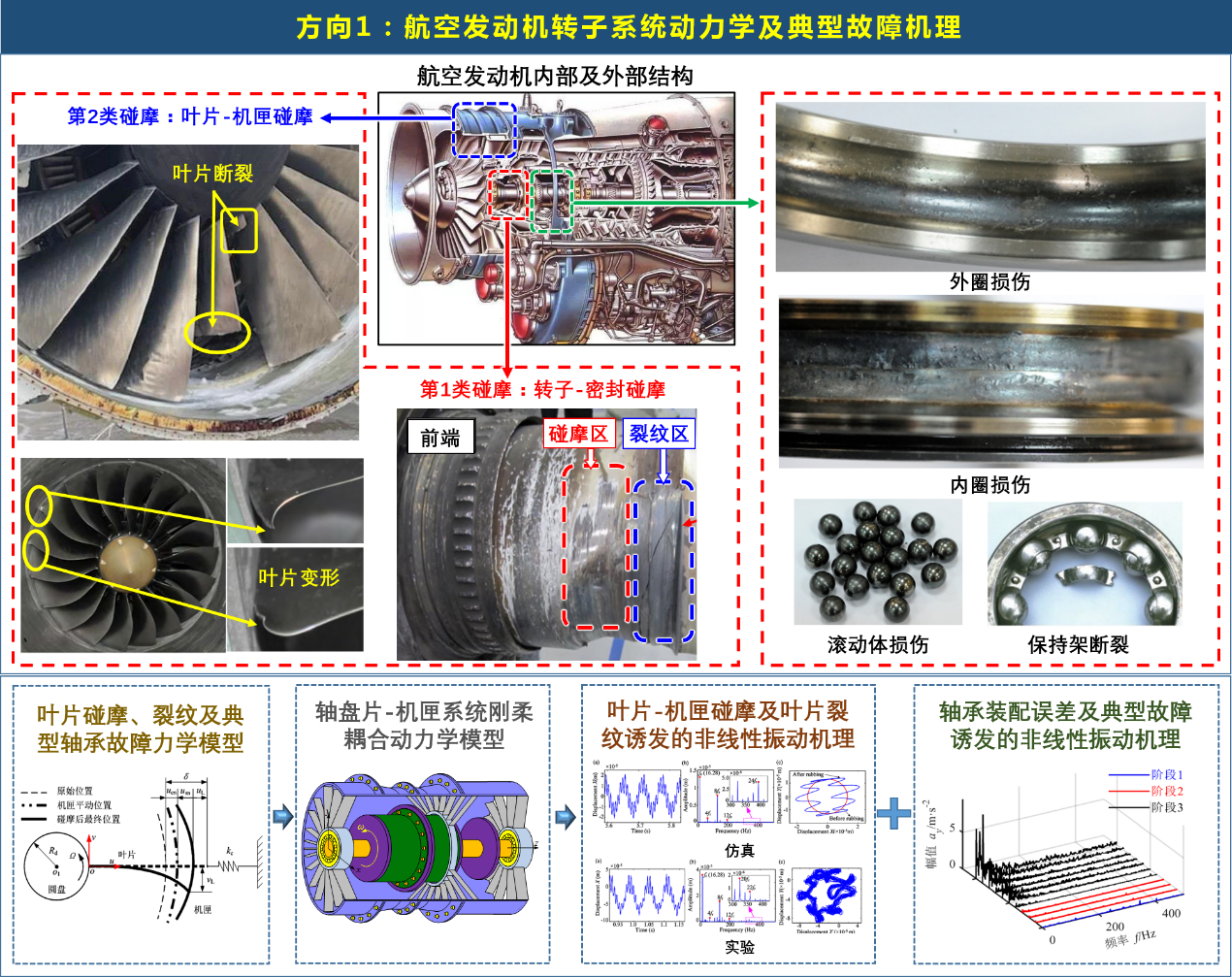

(1)方向1:航空发动机转子系统动力学及典型故障机理

针对航空发动机等高端旋转机械,构建叶片-机匣碰摩、叶片裂纹及典型轴承故障(内外圈及滚动体损伤、保持架断裂等)力学模型;考虑螺栓连接、套齿(花键)、联轴器、轴承等可能存在的非线性环节,采用半解析、有限元方法,提出轴盘片-机匣系统刚柔耦合动力学模型,并提出高效求解方法;揭示叶片-机匣碰摩、叶片裂纹、轴承装配误差及典型故障诱发的非线性振动机理。

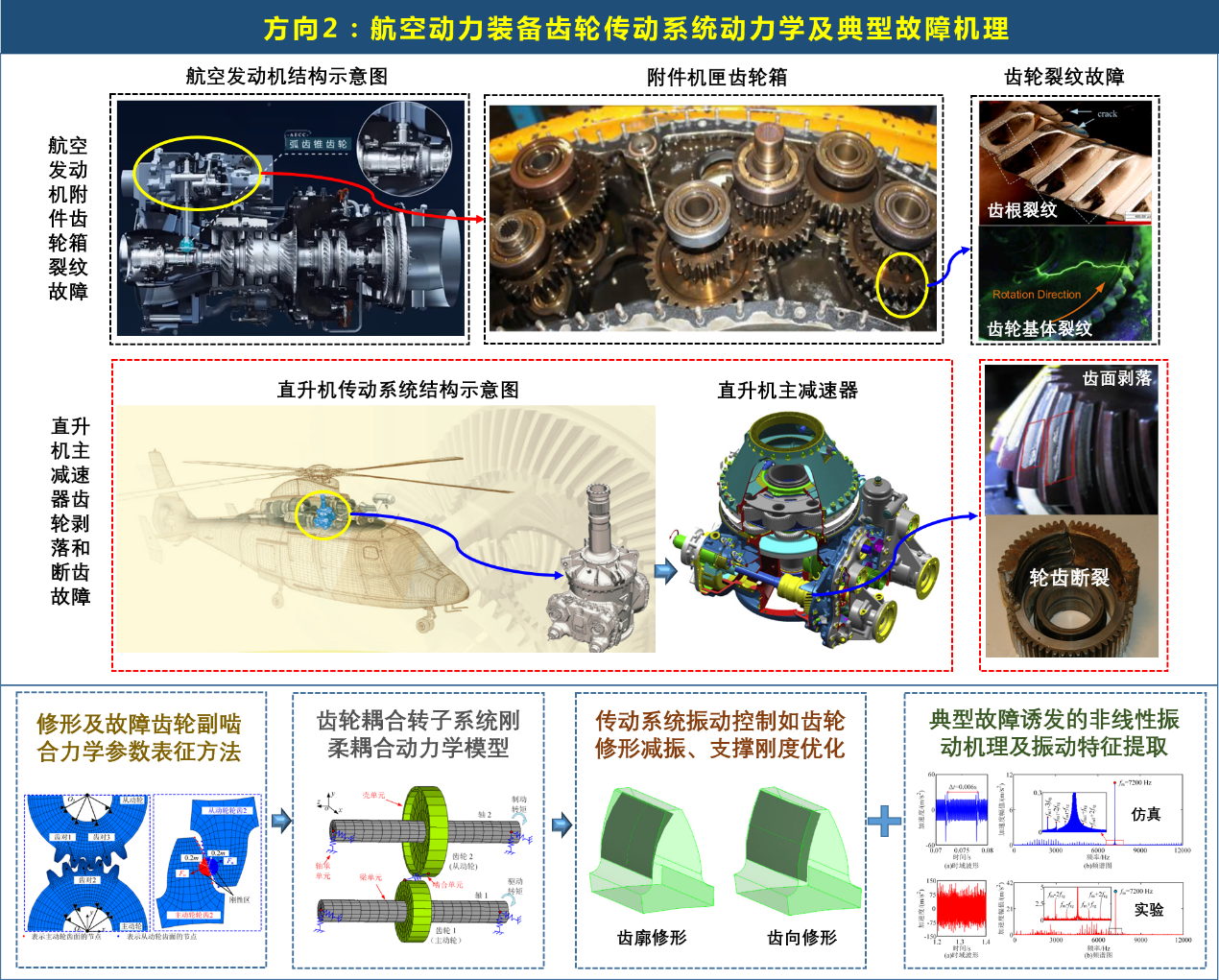

(2)方向2:航空动力装备齿轮传动系统动力学及典型故障机理

针对直升机主减速器、航空发动机附件机匣出现的典型故障,如齿轮裂纹、磨损和剥落等,提出含修形及故障齿轮副啮合力学参数(啮合刚度、传递误差等)表征方法;提出轴承-故障齿轮-转子系统刚柔耦合动力学建模方法;提出传动系统振动控制方法,如修形减振及支撑刚度优化等;揭示典型故障诱发的非线性振动机理,提取典型故障特征。

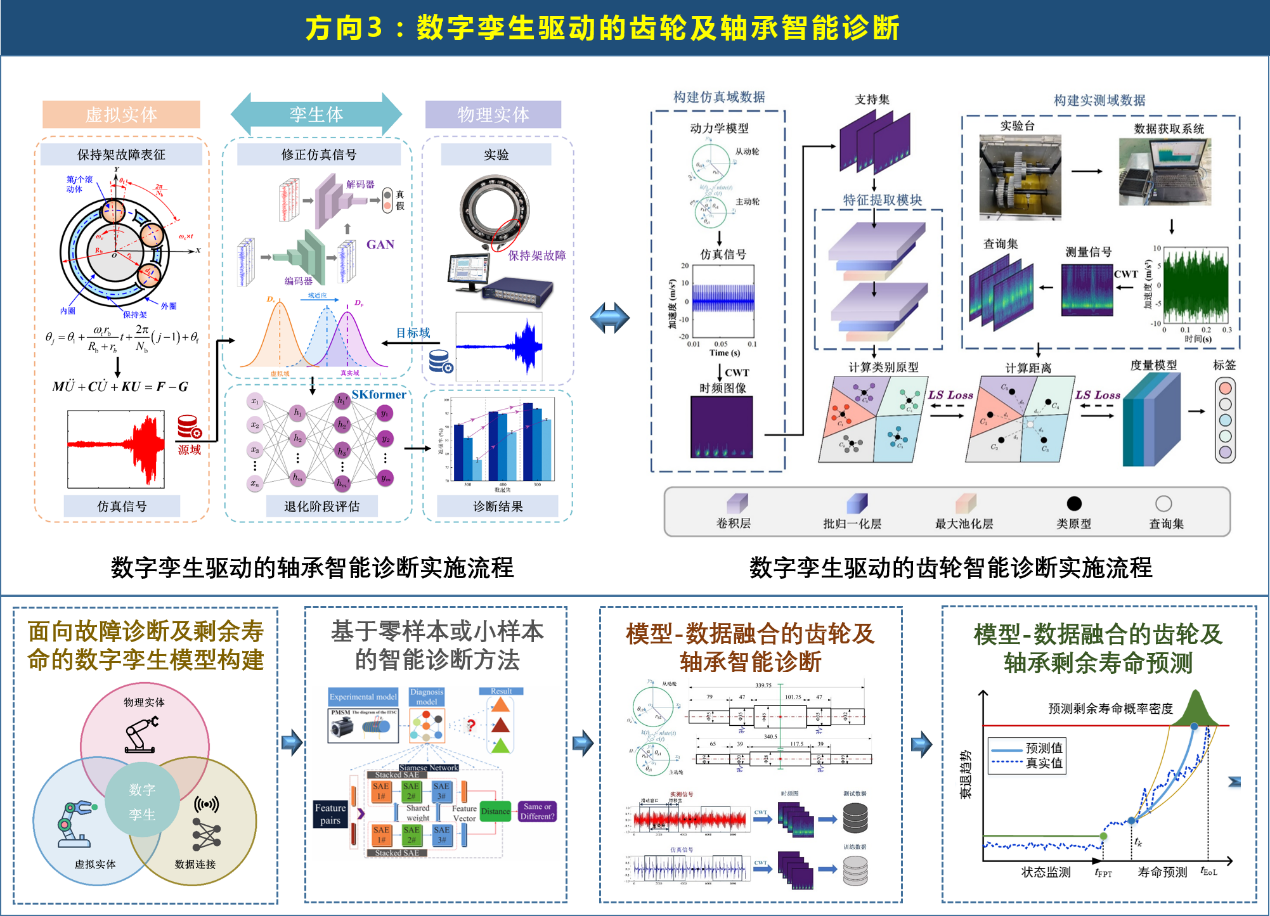

(3)方向3:数字孪生驱动的齿轮及轴承智能诊断

针对高端旋转机械齿轮、轴承等典型故障,如齿轮裂纹、轴承内外圈剥落和转静子碰摩等,面向故障诊断及剩余寿命构建含故障转子系统数字孪生模型;提出零样本或小样本工况下智能诊断方法;开展基于模型-数据混合驱动的齿轮、轴承及转子智能诊断方法;针对齿轮和轴承典型疲劳故障如裂纹、剥落等,提出基于模型-数据融合的剩余寿命预测方法。

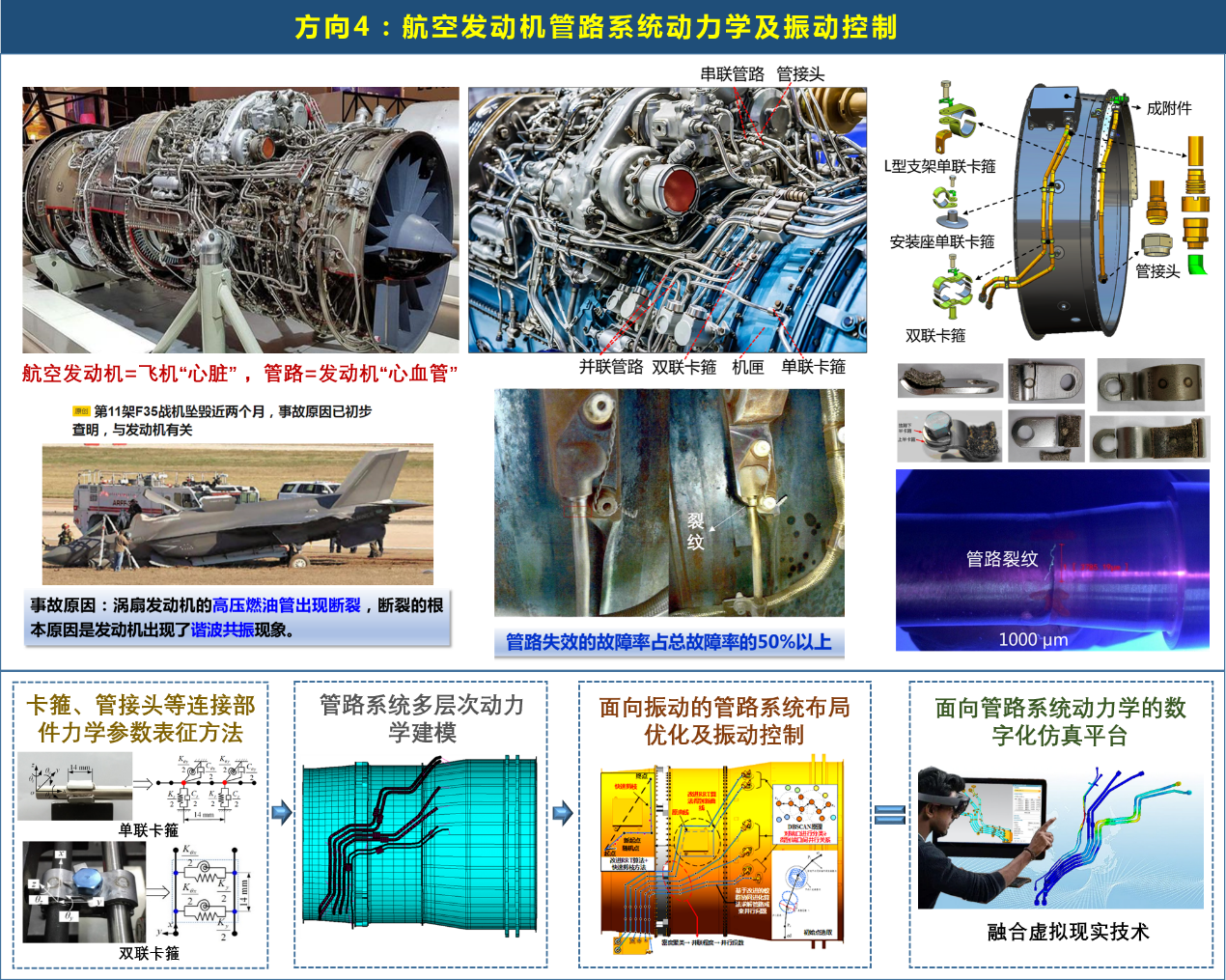

(4)方向4:航空发动机管路系统动力学及振动控制

针对航空发动机、飞机等外部管路系统,提出卡箍、管接头等典型连接部件力学参数表征方法;采用半解析、传递矩阵、有限元等方法,考虑流固耦合和结构耦合影响,构建复杂管路系统多层次动力学模型,分析管路系统动力学特性(固有频率、振动响应)及振动传递机制;提出面向管路系统动力学性能的优化设计方法,揭示卡箍、智能支撑结构等阻尼减振机理;开发面向管路系统动力学特性的数字化仿真平台。

论文成果

- **********************2025年度(25篇SCI,2篇EI)**********************.

- 1. Caizi Fan, Pengfei Wang, Yongchao Zhang*, Hui Ma*, Xiang Li, Qibin Wang. Digital twin assisted degradation assessment of bearing cage performance [J]. IEEE Transactions on Industrial Informatics, 2025, 21(7): 5171-5181. 【IF=9.9, Q1】.

- 2. Hong Guan, Hui Ma*, Xumin Guo, Qinqin Mu, Yao Zeng, Yanyan Chen. Axial rubbing-induced nonlinear vibration of shaft-disk system considering base motion [J]. Communications in Nonlinear Science and Numerical Simulation, 2025, 150: 109002. 【IF=3.8, Q1】.

- 3. Caizi Fan, Yongchao Zhang, Hui Ma*, Zeyu Ma. A novel deep denoising model integrating transformer and time-frequency loss for gearbox fault diagnosis [J]. Advanced Engineering Informatics, 2025, 66: 103400. 【IF=9.9, Q1】.

- 4. Hui Ma, Caizi Fan, Yongchao Zhang*, Qibin Wang*, Kun Yu, Zeyu Ma. Digital twin-inspired methods for rotating machinery intelligent fault diagnosis and remain useful life prediction: A state-of-the-art review and future challenges [J]. Mechanical Systems and Signal Processing, 2025, 232: 112770. 【IF=8.9, Q1】.

- 5. Zimeng Liu, Honghu Tian, Hui Ma*, Cheng Chang, Hansheng Song, Wenkang Huang, Jiazan Zhu, Pengyu Yan, Changqing Hu, Tianyu Zhao, Zhike Peng. Simulation and experimental analysis of traveling wave resonance of flexible spiral bevel gear system [J]. Mechanical Systems and Signal Processing, 2025, 224: 112071. 【IF=8.9, Q1】.

- 6. Weiwei Wang, Hong Guan, Hui Ma*, Haozhe Wang, Qinqin Mu, Yao Zeng, Yanyan Chen, Bangchun Wen. Dynamic stress analysis of a disc considering actual crack paths: Experiment and simulation [J]. Mechanical Systems and Signal Processing, 2025, 224: 112199. 【IF=8.9, Q1】.

- 7. Hong Guan, Pengfei Wang, Qian Xiong, Hui Ma*, Sainan Zhou, Qinqin Mu, Yao Zeng, Yanyan Chen. Modeling of misaligned bearing induced by coupling misalignment and assembly errors and vibration analysis in dual-rotor system [J]. Mechanical Systems and Signal Processing, 2025, 230: 112656. 【IF=8.9, Q1】.

- 8. Caizi Fan, Yongchao Zhang, Hui Ma*, Kun Yu, Zeyu Ma. A novel lightweight DDPM-based data augmentation method for rotating machinery fault diagnosis with small sample [J]. Mechanical Systems and Signal Processing, 2025, 232: 112741. 【IF=8.9, Q1】.

- 9. Yiming Cao, Hui Ma*, Xumin Guo, Weijiao Chen, Weiwei Wang, Tianyu Zhao, Junzhe Lin. Fluid pulsation excitation characterization and pipeline vibration response analysis [J]. Mechanical Systems and Signal Processing, 2025, 231: 112691. 【IF=8.9, Q1】.

- 10. Hong Guan, Hui Ma*, Xi Chen, Qinqin Mu, Yao Zeng, Yanyan Chen, Bangchun Wen, Xumin Guo. Nonlinear vibration of rotor-bearing system considering base-motion and bearing-misalignment [J]. Mechanism and Machine Theory, 2025, 206: 105933. 【IF=5.3, Q1】.

- 11. Zeyu Ma, Xiaojian Zhao, Yuping Wu, Hui Ma*, Peng Cao, Hong Guan, Zimeng Liu, Caizi Fan, Jiazan Zhu, Pengyu Yan, Zhike Peng. Two novel indicators for gear crack diagnosis based on vibration responses: Experiment and simulation [J]. Mechanism and Machine Theory, 2025, 205: 105905. 【IF=5.3, Q1】.

- 12. Wenkang Huang, Haodong Hu, Hui Ma*. Dynamic modeling and response analysis of cracked herringbone gear transmission systems with installation errors [J]. Mechanism and Machine Theory, 2025, 206: 105924. 【IF=5.3, Q1】.

- 13. Hong Guan, Xiangfu Ding, Hui Ma*, Bangchun Wen, Sainan Zhou, Qinqin Mu, Yao Zeng, Yanyan Chen. Dynamic characteristics of rotor system with initial bending induced by the misaligned four-point contact ball bearing [J]. Mechanism and Machine Theory, 2025, 209 : 106017. 【IF=5.3, Q1】.

- 14. Jinyuan Tian, Xumin Yin, Hongyang Xu, Hui Ma*, Pengfei Wang, Xiaoxu Zhang, Songtao Zhao. Nonlinear characteristics in the cylindrical roller bearing with raceway defects [J]. Applied Mathematical Modelling, 2025, 138: 115760. 【IF=5.1, Q1】.

- 15. Pengfei Wang, Xiang Zhao, Hongyang Xu, Hui Ma*, Xunmin Yin, Xiaoxu Zhang, Songtao Zhao. Nonlinear dynamic behaviors of a shaft-bearing-pedestal system with outer ring slip and damage [J]. Nonlinear Dynamics, 2025, 113: 3171-3199. 【IF=6, Q1】.

- 16. Weijiao Chen, Xiaochi Qu, Ruixin Zhang, Xumin Guo, Hui Ma*, Bangchun Wen. Nonlinear stress analysis of aero-engine pipeline based on semi-analytical method [J]. Applied Mathematics and Mechanics (English Edition), 2025, 46(3): 521-538. 【IF=4.8, Q1】.

- 17. Xiaochi Qu, Weijiao Chen, Xumin Guo, Hui Ma*, Ziwei Guo, Shuo Chen, Ruixin Zhang. Precise modeling and stress response analysis of the aero-engine clamp: A simulation and experimental study [J]. Mechanics Based Design of Structures and Machines, 2025, 53(3): 2000-2020. 【SCI: 001308220800001】【IF=2.9, Q2】.

- 18. Qiang Fu, Jin Zeng, Hui Ma*, Bo Wang, Xin Wang, Bingjie Zhang. A mechanical calculation model for the nonlinear mechanical behavior of the metal rubber clamp in aero engine [J]. Mechanics Based Design of Structures and Machines, 2025, 53(4): 3159-3178. 【IF=2.9, Q2】.

- 19. Xiaojian Zhao, Hui Ma*, Zeyu Ma, Jiaqi Liu, Peng Cao, Yuping Wu, Xiangfu Ding, Tianyu Zhao, Optimization of mesh characteristics of gear pair considering the influence of assembly errors [J]. Journal of Central South University, 2025, 32: 1400-1430. 【IF=4.4, Q1】.

- 20. Qian Xiong, Ping Zhang, Chang Liu, Muxiao Li, Xing Liu, Hui Ma*. Natural characteristic analysis of cracked blade and its application in crack localization [J]. Mechanics Based Design of Structures and Machines, 2025, DOI: 10.1080/15397734.2025.2480703. 【IF=2.9, Q2】.

- 21. Hui Ma*, Hong Guan, Lin Qu, Xumin Guo, Qinqin Mu, Yao Zeng, Yanyan Chen. Dynamic modeling and simulation of blade-casing system with rubbing considering time-varying stiffness and mass of casing [J]. Applied Mathematics and Mechanics (English Edition), 2025, 46(5): 849-868. 【IF=4.8, Q1】.

- 22. Caizi Fan, Yongchao Zhang, Hui Ma*, Zeyu Ma, Xunmin Yin, Xiaoxu Zhang, Songtao Zhao. A novel imbalance fault diagnosis method based on data augmentation and hybrid deep learning model [J]. Structural Health Monitoring-An International Journal, 2024, DOI: 10.1177/14759217241291143. 【IF=5.7, Q1】.

- 23. Hui Ma, Guan Hong*, Duo He, Sainan Zhou, Miao Yu, Luning Men, Qinqin Mu, Yao Zenge, Yanyan Chen. Nonlinear vibration of cylindrical roller bearing considering the surface roughness: simulation and experiment [J]. Nonlinear Dynamics, 2025, accepted. 【IF=6, Q1】.

- 24. Ning Liu, Hui Ma*, Hong Guan, Sainan Zhou, Tianyu Zhao, Peng Cao, Yuping Wu. Meshing characteristics of planetary gear system considering tooth surface roughness and elastohydrodynamic lubrication [J]. Journal of Central South University, 2025, accepted. 【IF=4.4, Q1】.

- 25. Weiwei Wang, Hui Ma*, Chenguang Zhao. Investigation of nonlinear vibrations in rotating cracked blades based on a semi-analytical method [J]. Mechanics Based Design of Structures and Machines, 2025, accepted..

- 26. 刘明, 王鹏飞, 官宏, 马辉. 含耦合不对中的深沟球轴承灵敏度分析[J]. 东北大学学报(自然科学版), 2025, 46(1): 83-91. .

- 27. 官宏, 熊茜, 马辉, 汪伟伟. 旋转叶片裂纹故障特征提取与分析[J]. 东北大学学报(自然科学版), 2025, 46(3): 60-68..

- 28. 杜宇彤, 马辉, 慕琴琴. 膜盘联轴器轴向刚度特性分析[J]. 航空科学技术, 2025, 36(1): 56-63. 【核心期刊】.

- 29. 郭子巍, 郭旭民, 陈硕, 马辉. 单联卡箍-L型支架等效刚度仿真及试验验证[J]. 航空发动机, 2024, 录用待刊。.

- ******************2024年度(29篇SCI,2篇EI)******************.

- 1. Songtao Zhao, Ming Liu, Hui Ma*, Hong Guan*,·Shan Chang, Xinxing Ma, Bangchun Wen. Effect of SFD on rubbing‑induced vibration characteristics in dual-rotor-blade-casing system [J]. Meccanica, 2024, 59: 2265-2281. 【SCI, IF=1.9, Q2】.

- 2. Zimeng Liu, Cheng Chang, Haodong Hu, Hui Ma*, Kaigang Yuan, Xin Li, Xiaojian Zhao, Zhike Peng. Dynamic characteristics of spur gear system with tooth root crack considering gearbox flexibility [J]. Mechanical Systems and Signal Processing, 2024, 208: 110966. 【SCI: 001127797400001, IF=7.9, Q1】.

- 3. Hong Guan, Qian Xiong, Hui Ma*, Yang Yang, Jin Zeng, Pengfei Wang, Yingli Bao. Study on dynamic characteristics of the gear-dual-rotor system with multi-position rubbing [J]. Mechanism and Machine Theory, 2024, 191: 105501. 【SCI: 001091088600001, IF=4.5, Q1】.

- 4. Pengfei Wang, Hongyang Xu, Hui Ma*, Yang Yang, Qingkai Han, Bangchun Wen, Xiaopeng Li. Nonlinear response of rotor system with bearing dynamic misalignment [J]. Mechanics Based Design of Structures and Machines, 2024, 52(5): 2532-2553. 【SCI: 000945638100001 , IF=2.9, Q2】.

- 5. Hongyang Xu, Xiang Zhao, Hui Ma*, Zhong Luo, Qingkai Han, Bangchun Wen. Vibration analysis of a gear-rotor-bearing system with outer-ring spalling and misalignment [J]. Journal of Central South University, 2024, 31: 508-522. 【SCI: 001190975700018, IF=3.7, Q1】.

- 6. Hong Guan, Hui Ma*, Xiaochi Qu, Zhiyuan Wu, Jin Zeng, Qian Xiong, Hongji Wang. Dynamic stress analysis of cracked rectangular blade: simulation and experiment [J]. International Journal of Mechanical Sciences, 2024, 267: 109015. 【SCI: 001153270700001, IF=7.1, Q1】.

- 7. Hongyang Xu, Hui Ma*, Baogang Wen, Yang Yang, Xiaopeng Li, Zhong Luo, Qingkai Han, Bangchun Wen. Dynamic characteristics of spindle-bearing with tilted pedestal and clearance fit [J]. International Journal of Mechanical Sciences, 2024, 261: 108683. 【SCI: 001149419700001, IF=7.1, Q1】.

- 8. Weijiao Chen, Yiming Cao, Xumin Guo, Hui Ma*, Bangchun Wen, Bo Wang. Semi-analytical dynamic modeling and fluid-structure interaction analysis of L-shaped pipeline [J]. Thin-Walled Structures, 2024, 196: 111485. 【SCI: 001143597800001, IF=5.7, Q1】.

- 9. Weiwei Wang, Hui Ma*, Chenguang Zhao, Zhiyuan Wu, Hongji Wang. Dynamic contact characteristics of a rotating twisted variable-section blade with breathing crack [J]. Journal of Central South University, 2024, 31: 858-877. 【SCI: 001205267600009 , IF=3.7, Q1】.

- 10. Wenkang Huang, Zhanwei Li, Hui Ma*, Jiazan Zhu, Zimeng Liu, Hansheng Song, Haodong Hu, Xin Li, Yang Yang, Zhike Peng. A novel analytical method for meshing characteristics of spiral bevel gears considering slice coupling [J]. Mechanism and Machine Theory, 2024, 195: 105591. 【SCI: 001178142900001, IF=4.5, Q1】.

- 11. Hongji Wang, Hui Ma*, Weiwei Wang, Hong Guan, Zhiyuan Wu. Analysis and experimental verification of dynamic characteristics of cantilever plate with fatigue crack [J]. Engineering Failure Analysis, 2024, 157: 107918. 第1作者为东大本科生【SCI: 001150889700001, IF=4.4, Q1】.

- 12. Caizi Fan, Yongchao Zhang, Hui Ma*, Zeyu Ma, Kun Yu, Songtao Zhao, Xiaoyu Zhang. A novel metric-based model with the ability of zero-shot learning for intelligent fault diagnosis [J]. Engineering Applications of Artificial Intelligence, 2024, 129: 107605. 【SCI: 001132377200001, IF=7.5, Q1】.

- 13. Kai Yan, Tianyu Zhao*, Hui Ma*. Coupled vibration analysis of a rotating pre-twist blade-hub assembly with a setting angle reinforced by graphene nanoplatelets [J]. Thin–Walled Structures, 2024, 195: 111287. 【SCI: 001122502800001, IF=5.7, Q1】.

- 14. Pengfei Wang, Xiang Zhao, Yang Yang, Hui Ma*, Qingkai Han, Zhong Luo, Xiaopeng Li, Bangchun Wen. Dynamic modeling and analysis of two-span rotor-pedestal system with bearing tilt and extended defect: Simulation and experiment [J]. Applied Mathematical Modelling, 2024, 125: 1-28. 【SCI: 001091088600001, IF=4.4, Q1】.

- 15. Hui Ma*, Hong Guan, Lin Qu, Tianrui Yang, Yao Zeng, Yanyan Chen, Zhimin Zhu, Hongji Wang. Blade-coating-casing rubbing induced vibration responses and wear characteristics [J]. Tribology International, 2024, 194: 109571. 【SCI: 001178142900001, IF=6.1, Q1】.

- 16. Weijiao Chen, Ziwei Guo, Shuo Chen, Yiming Cao, Xumin Guo, Hui Ma*, Bangchun Wen. Semi-analytic modeling and experimental verification of arbitrary aero-engine complex spatial pipeline [J]. Applied Mathematical Modelling, 2024, 131: 505-534. 【SCI:, IF=4.4, Q1】.

- 17. Yiming Cao, Hui Ma*, Xumin Guo, Bingfeng Zhao, Hui Li, Xi Wang, Bing Wang. Comparison of nonlinear modeling methods for composite rubber clamp [J]. Applied Mathematics and Mechanics (English Edition), 2024, 45(5): 763-778. 【SCI:, IF=4.5, Q1】.

- 18. Hongxu Tian, Xiaojian Zhao, Wenkang Huang, Hui Ma*. A stiffness model for EHL contact on smooth / rough surfaces and its application in mesh stiffness calculation of the planetary gear set [J]. Tribology International, 2024, 196: 109720. 【SCI:, IF=6.1, Q1】.

- 19. Hong Guan, Qian Xiong, Hui Ma*, Weiwei Wang, Kaixuan Ni, Zhiyuan Wu, Xunmin Yin, Songtao Zhao, Xiaoxu Zhang. Comparison of nonlinear vibration responses induced by edge crack and surface crack of compressor blades [J]. Mechanical Systems and Signal Processing, 2024, 216: 111465. 【SCI:, IF=7.9, Q1】.

- 20. Xumin Guo, Hui Ma*, Han Ge, Shuo Chen, Bangchun Wen. Vibration transmission characteristics analysis of a flexible casing-multiple pipes system [J]. Mechanical Systems and Signal Processing, 2024, 217: 111536. 【SCI:, IF=7.9, Q1】.

- 21. Hong Guan, Kaixuan Ni, Hui Ma*, Qian Xiong, Weiwei Wang, Hongji Wang. Dynamic modeling and verification of rotating compressor blade with crack based on beam element [J]. Applied Mathematical Modelling, 2024, 133: 367-393. 【SCI:, IF=4.4, Q1】.

- 22. Zimeng Liu, Cheng Chang, Haodong Hu, Hui Ma*, Shunhao Zhang, Songtao Zhao, Xiaoxu Zhang, Zhike Peng. Meshing characteristic analysis of spur gear pair with tooth surface wear fault based on improved fractal method [J]. Journal of Central South University, 2024, 31: 1619-1636. 【SCI: , IF=3.7, Q1】.

- 23. Pengfei Wang, Yang Yang, Baogang Wen, Hui Ma*, Qingkai Han, Zhong Luo, Xiaopeng Li, Bangchun Wen. Numerical and experimental analysis of vibration characteristics of spindle system under bearing assembly errors [J]. Mechanics Based Design of Structures and Machines, 2024, 52(8): 4811-4838. 【SCI: 001031481500001 , IF=2.9, Q2】.

- 24. Hong Guan, Hui Ma*, Yang Yang, Pengfei Wang, Hongyang Xu, Qian Xiong, Ming Liu. Vibration characteristic investigation of an eccentric rotor system with rubbing [J]. Mechanics Based Design of Structures and Machines, 2024, 52(9): 6275–6304. 【SCI: 001102055900001, IF=2.9, Q2】.

- 25. Ning Liu, Hui Ma*, Zhifang Zhao, Pengfei Wang, Xiaojian Zhao. Dynamic characteristics of gear-rotor system with gear eccentricity and wear fault [J]. Nonlinear Dynamics, 2024, 112: 16003-16035. 【SCI: , IF=5.2, Q1】.

- 26. Wenkang Huang, Zimeng Liu, Hui Ma*, Haimin Zhu*, Yao Zeng, Yanyan Chen, Hong Guan. Self-excited vibration analysis of spline rotor systems considering parallel and angular misalignments [J]. Tribology International, 2024, 198: 109920. 【SCI: , IF=6.1, Q1】.

- 27. Caizi Fan, Pengfei Wang, Hui Ma*, Yongchao Zhang, Zeyu Ma, Xunmin Yin, Xiaoxu Zhang, Songtao Zhao. Performance degradation assessment of rolling bearing cage failure based on enhanced CycleGAN [J]. Expert Systems With Applications, 2024, 255: 124697. 【SCI: , IF=7.5, Q1】.

- 28. Yong Zhang, Shuhua yang, Xingyu Tai, Hui Ma*, Hong Guan*, Qinqin Mu, Lin Qu, Xiangfu Ding. Study on rubbing-induced vibration characteristics considering the flexibility of coated casings and blades [J]. Machines, 2024, 12: 481. 【 , IF=2.1, Q2】.

- 29. Hongxu Tian, Hui Ma*, Zhike Peng, Jiazan Zhu, Songtao Zhao, Xiaoxu Zhang. Study on rigid-flexible coupling modeling of planetary gear systems: Incorporation of the pass effect and random excitations [J]. Mechanism and Machine Theory, 2024, 201: 105745. 【 , IF=4.5, Q1】.

- 30. 李晖, 谷建霏, 李济楠, 孙占彬, 孙凯华, 刘小川, 王鑫, 张丙杰, 王相平, 马辉*. 多源激励下航空发动机L型管路动力学建模与验证[J]. 航空学报, 2024, 45(12): 229375. 【EI】.

- 31. 宋翰生, 马辉*, 刘子濛, 黄文康. 含有不同裂纹类型的弧齿锥齿轮副啮合特性分析[J]. 东北大学学报(自然科学版), 2024, 45(8): 1096-1106. 【EI】.

- ************************2023年度(25篇SCI,3篇EI)************************.

- 1.Wenkang Huang, Hui Ma*, Zhifang Zhao, Pengfei Wang, Zhike Peng, Xiaoxu Zhang, Songtao Zhao. An iterative model for mesh stiffness of spur gears considering slice coupling under elastohydrodynamic lubrication [J]. Journal of Central South University, 2023, 30: 3414-3434. 【SCI】.

- 2.Weiwei Wang, Kaixuan Ni, Hui Ma*, Qian Xiong, Zhiyuan Wang, Hongji Wang, Caizi Fan. Fatigue crack propagation simulation of airfoil section blade under aerodynamic and centrifugal loads [J]. Engineering Fracture Mechanics, 2023, 293: 109702. 【SCI】.

- 3.Zimeng Liu, Erliang Shang,Yifan Huangfu, Hui Ma*, Jiazan Zhu, Songtao Zhao, Xinhua Long, Zhanwei Li. Vibration characteristics analysis of flexible helical gear system with multi-tooth spalling fault: simulation and experimental study [J]. Mechanical Systems and Signal Processing, 2023, 201:110687. 【SCI】.

- 4.Yiming Cao, Weijiao Chen, Hui Ma*, Hui Li, Bing Wang, Li Tan, Xin Wang, Qingkai Han. Dynamic modeling and experimental verification of clamp-pipeline system with soft nonlinearity [J]. Nonlinear Dynamics, 2023, 111: 17725–17748. 【SCI】.

- 5.Qian Xiong, Hong Guan, Hui Ma*, Zhiyuan Wu, Jin Zeng, Weiwei Wang, Hongji Wang. Crack propagation and induced vibration characteristics of cracked cantilever plates under resonance state: Experiment and simulation [J]. Mechanical Systems and Signal Processing, 2023, 201: 110674. 【SCI】.

- 6.Weijiao Chen, Yiming Cao, Shuo Chen, Xumin Guo, Hui Ma*, Bangchun Wen. Semi-analytical dynamic modeling of parallel pipeline considering soft nonlinearity of clamp: A simulation and experimental study [J]. Mechanical Systems and Signal Processing, 2023, 201: 110648. 【SCI】.

- 7.Hongzheng Han, Hui Ma*, Hongxu Tian, Zhike Peng, Jiazan Zhu, Zhanwei Li. Sideband analysis of cracked planetary gear train considering output shaft radial assembly error [J]. Mechanical Systems and Signal Processing, 2023, 200: 110618. 【SCI】.

- 8.Hongyang Xu, Pengfei Wang, Hui Ma*, Yang Yang, Xiaopeng Li, Zhong Luo, Qingkai Han, Bangchun Wen. Dynamic behaviors and contact characteristics of ball bearings in a multi-supported rotor system under the effects of 3D clearance fit [J]. Mechanical Systems and Signal Processing, 2023, 196: 110334. 【SCI】.

- 9.Qian Xiong, Hong Guan, Hui Ma*, Zhiyuan Wu; Xumin Guo; Weiwei Wang. Dynamic characteristic analysis of a rotating aero-engine blade with breathing penetrating crack [J]. Mechanical Systems and Signal Processing, 2023, 196: 110325. 【SCI】.

- 10.Yiming Cao, Xumin Guo, Hui Ma*, Han Ge, Hui Li, Junzhe Lin, Duo Jia, Bing Wang, Yongchun Ma. Dynamic modelling and natural characteristics analysis of fluid conveying pipeline with connecting hose [J]. Mechanical Systems and Signal Processing, 2023, 193: 110244. 【SCI】.

- 11.Xumin Guo, Peixin Gao, Hui Ma*, Hui Li, Bo Wang, Qingkai Han, Bangchun Wen. Vibration characteristics analysis of fluid-conveying pipes concurrently subjected to base excitation and pulsation excitation [J]. Mechanical Systems and Signal Processing, 2023, 189: 110086. 【SCI】.

- 12.Pengfei Wang, Yang Yang, Hui Ma*, Hongyang Xu, Xu Li, Zhong Luo, Bangchun Wen. Vibration characteristics of rotor-bearing system with angular misalignment and cage fracture: simulation and experiment [J]. Mechanical Systems and Signal Processing, 2023, 182: 109545. 【SCI】.

- 13.Xumin Guo, Jin Zeng, Hui Ma*, Shiyu Liu, Zhong Luo, Chaofeng Li, Qingkai Han, Bangchun Wen. Semi-analytical modeling and experimental verification of a flexible varying section disk-blades system with elastic supports [J]. Thin-walled Structures, 2023, 185: 110563. 【SCI】.

- 14.Pengfei Wang, Yang Yang, Hongyang Xu, Hui Ma*, Qingkai Han, Zhong Luo, Bangchun Wen. Effect of static and dynamic misalignment of rolling bearing on nonlinear vibration characteristics of rotor system [J]. Journal of Central South University, 2023, 30: 871-903. 【SCI】.

- 15.Zhang X, Yang Y*, Ma H*, et al. A novel diagnosis indicator for rub-impact of rotor system via energy method [J]. Mechanical Systems and Signal Processing, 2023, 185: 109825. 【SCI】.

- 16.Bingfeng Zhao, Jiaxin Song*, Liyang Xie, Hui Ma*, Hui Li, Jungang Ren, Weiqiao Sun. Multiaxial fatigue life prediction method based on the back-propagation neural network [J]. International Journal of Fatigue, 2023, 166: 107274. 【SCI】.

- 17.Yang Yang, Hui Liu, Hui Ma*, Pengfei Wang*, Qingkai Han, Bangchun Wen. Experimental study on vibration characteristics due to cage damage of deep groove ball bearing [J]. Tribology International, 2023, 185: 108555. 【SCI】.

- 18.Qiao Z, Chen K, Zhou C, Hui Ma*. An improved fault model of wind turbine gear drive under multi-stage cracks [J]. Simulation Modelling Practice and Theory, 2023, 122: 102679. 【SCI】.

- 19.Hongxu Tian, Haixu Wang, Xiaoyu Zhao, Hui Ma*. Dynamic modeling of GTF star gear-rotor coupling system considering structural flexibility [J]. Journal of Sound and Vibration, 2023, 560: 117813. 【SCI】.

- 20.Wenkang Huang, Hongxu Tian, Hui Ma*, Pengfei Wang, Yang Yang, Qingkai Han. An improved method for calculating the lateral and angular stiffness of spline couplings considering parallel misalignment [J]. Mechanism and Machine Theory, 2023, 189: 105436. 【SCI】.

- 21.Hongzheng Han, Kaigang Yuan, Hui Ma*, Zhike Peng, Zhanwei Li, Songtao Zhao, Bangchun Wen. Mesh characteristic analysis and dynamic simulation of spur gear pair considering corner contact and tooth broken fault [J]. Engineering Failure Analysis, 2023, 143: 106883. 【SCI】.

- 22.Jinyuan Tian, Pengfei Wang, Hongyang Xu, Hui Ma*, Xiang Zhao. Nonlinear vibration characteristics of rolling bearing considering flexible cage fracture [J]. International Journal of Non-Linear Mechanics, 2023, 156: 104478. 【SCI】.

- 23.Hongxu Tian, Wenkang Huang, Zimeng Liu, Hui Ma*. Analysis of dynamic mesh stiffness and dynamic response of helical gear based on sparse polynomial chaos expansion [J]. Machines, 2023, 11: 736. 【SCI】.

- 24.Zhifang Zhao, Yang Yang, Hui Ma*, Haixu Wang, Hongxu Tian, Chenyi Han. Meshing characteristics of spur gear pairs with tooth modification under different assembly errors and sensitivity analysis for impact factors [J]. Journal of Mechanical Science and Technology, 2023, 37(1): 149-162. 【SCI】.

- 25.Yiming Cao, Hui Ma*, Xumin Guo, Han Ge, Hui Li, Junzhe Lin. Experimental study on pressure pulsation and acceleration response of fluid conveying pipeline under multi-excitation [J]. ASME Journal of Pressure Vessel Technology, 2023, 145: 051401. 【SCI】.

- 26.王鹏飞, 徐宏阳, 马辉*, 杨阳. 含轴承倾斜不对中的行星轮系-转子系统动态特性研究 [J]. 振动工程学报, 2023, 36(1): 116-127. 【EI】.

- 27.徐宏阳,杨阳,王鹏飞,马辉*. 不对中及外载荷作用下含滚珠分布误差的深沟球轴承刚度波动特性 [J]. 东北大学学报(自然科学版), 2023, 44(3): 382-391. 【EI】.

- 28.熊茜, 马辉*, 官宏. 斜裂纹旋转叶片动力学建模及振动响应分析 [J]. 哈尔滨工业大学学报, 2023, 55(12): 66-75. 【EI】.

- ************************2022年度(22篇SCI,6篇EI)************************.

- 1.Yiming Cao, Qingdong Chai, Xumin Guo, Hui Ma*, Pengfei Wang, Comparative study on two finite element models for multi-clamp pipeline system [J]. Journal of Mechanical Science and Technology, 2022, 36(3): 1157-1169.【SCI】.

- 2.Duo He, Yang Yang, Hongyang Xu, Hui Ma*, Xiang Zhao, Dynamic analysis of rolling bearings with roller spalling defects based on explicit finite element method and experiment [J]. Journal of Nonlinear Mathematical Physics, 2022, 29(2): 219-243.【SCI】.

- 3.Hongxu Tian, Hongzheng Han, Zhifang Zhao, Chenyi Han, Hui Ma*. Wear prediction and meshing characteristics for the planetary gear set considering angular misalignment and rotating carrier [J]. Engineering Failure Analysis, 2022, 140: 106583.【SCI&EI】.

- 4.Zhifang Zhao, Yang Yang, Hongzheng Han, Hui Ma*, Haixu Wang, Zhanwei Li. Meshing characteristics of spur gears considering three-dimensional fractal rough surface under elastohydrodynamic lubrication [J]. Machines, 2022, 10: 705.【SCI】.

- 5.Zimeng Liu, Yifan Huangfu, Hui Ma*, Zhike Peng, Jiazan Zhu, Haixu Wang, Zhanwei Li. Traveling wave resonance analysis of flexible spur gear system with angular misalignment [J]. International Journal of Mechanical Sciences, 2022, 232: 107617.【SCI】.

- 6.Hongzheng Han, Hui Ma*, Haixu Wang, Jiazan Zhu, Zhanwei Li, Zimeng Liu. Dynamic simulation of cracked spiral bevel gear pair considering assembly errors [J]. Machines, 2022, 10: 929.【SCI】.

- 7.Hongzheng Han, Shunhao Zhang, Yang Yang, Hui Ma*, Lingli Jiang. Modulation sidebands analysis of coupled bevel gear pair and planetary gear train system [J]. Mechanism and Machine Theory, 2022, 176: 104979.【SCI】.

- 8.Zhao Tianyu, Li Kun, Hui Ma*. Study on dynamic characteristics of a rotating cylindrical shell with uncertain parameters [J]. Analysis and Mathematical Physics, 2022, 12: 97.【SCI】.

- 9.Weijiao Chen, Yiming Cao, Xumin Guo, Hui Ma*, Bangchun Wen, Bo Wang. Nonlinear vibration analysis of pipeline considering the effects of soft nonlinear clamp [J]. Applied Mathematics and Mechanics (English Edition), 2022, 43(10), 1555–1568.【SCI&EI】.

- 10.Tianrui Yang, Hui Ma*, Zhaoye Qin, Hong Guan, Qian Xiong. Coupling vibration characteristics of the shaft-disk-drum rotor system with bolted joints [J]. Mechanical Systems and Signal Processing, 2022, 169: 108747. 【SCI】.

- 11.Kangkang Chen, Yifan Huangfu, Zhifang Zhao, Hui Ma*, Xingjian Dong, Dynamic modeling of the gear-rotor systems with spatial propagation crack and complicated foundation structure [J]. Mechanism and Machine Theory, 2022, 172: 108749. 【SCI&EI】.

- 12.Hongyang Xu, Pengfei Wang, Hui Ma*, Duo He, Xiang Zhao, Yingli Bao, Yang Yang. Contact characteristics analysis of deep groove ball bearings under combined angular misalignments and external loads [J]. Journal of Tribology-Transactions of The ASME, 2022, 144: 121201.【SCI】.

- 13.Hongyang Xu, Pengfei Wang, Yang Yang, Hui Ma*, Zhong Luo, Qingkai Han, Bangchun Wen. Effects of supporting stiffness of deep groove ball bearings with raceway misalignment on vibration behaviors of a gear-rotor system [J]. Mechanism and Machine Theory, 2022, 177: 105041.【SCI】.

- 14.Hongyang Xu, Yang Yang, Hui Ma*, Zhong Luo, Xiaopeng Li, Qingkai Han, Bangchun Wen. Vibration characteristics of bearing-rotor systems with inner ring dynamic misalignment [J]. International Journal of Mechanical Sciences, 2022, 230: 107536. 【SCI:&EI】.

- 15.Hongyang Xu, Pengfei Wang, Hui Ma*, Duo He, Xiang Zhao, Yang Yang, Analysis of axial and overturning ultimate load-bearing capacities of deep groove ball bearings under combined loads and arbitrary rotation speed [J]. Mechanism and Machine Theory, 2022, 169: 104665.【SCI】.

- 16.Pengfei Wang, Hongyang Xu, Yang Yang, Hui Ma*, Duo He, Xiang Zhao, Dynamic characteristics of ball bearing-coupling-rotor system with angular misalignment fault [J]. Nonlinear Dynamics, 2022, 108(4): 3391-3415.【SCI&EI】.

- 17.Pengfei Wang, Hongyang Xu, Hui Ma*, Hongzheng Han, Yang Yang, Effects of three types of bearing misalignments on dynamic characteristics of planetary gear set-rotor system [J]. Mechanical Systems and Signal Processing, 2022, 169: 108736. 【SCI&EI】.

- 18.Xumin Guo, Yiming Cao, Hui Ma*, Hui Li, Bo Wang, Qingkai Han, Bangchun Wen. Vibration analysis for a parallel fluid-filled pipelines-casing model considering casing flexibility [J]. International Journal of Mechanical Sciences, 2022, 231: 107606. 【SCI】.

- 19.Xumin Guo, Yiming Cao, Hui Ma*, Chunliang Xiao, Bangchun Wen. Dynamic analysis of an L-shaped liquid-filled pipe with interval uncertainty [J]. International Journal of Mechanical Sciences, 2022, 217: 107040. 【SCI】.

- 20.Xumin Guo, Chunliang Xiao, Han Ge, Hui Ma*, Hui Li, Wei Sun, Zhonghua Liu, Dynamic modeling and experimental study of a complex fluid-conveying pipeline system with series and parallel structures [J]. Applied Mathematical Modelling, 2022, 109: 186-208.【SCI】.

- 21.Xumin Guo, Han Ge, Chunliang Xiao, Hui Ma*, Wei Sun, Hui Li, Vibration transmission characteristics analysis of the parallel fluid-conveying pipes system: Numerical and experimental studies [J]. Mechanical Systems and Signal Processing, 2022, 177: 109180.【SCI】.

- 22.Xumin Guo, Chunliang Xiao, Hui Ma*, Hui Li, Xufang Zhang, Bangchun Wen. An improved frequency modeling and solution for parallel liquid-filled pipes considering both fluid-structure interaction and structural coupling [J]. Applied Mathematics and Mechanics (English Edition), 2022, 43(8): 1269-1288.【SCI】.

- 23.汪博, 高培鑫, 马辉*, 孙伟, 林君哲, 李晖, 韩清凯, 刘中华. 航空发动机管路系统动力学特性研究综述[J]. 航空学报, 2022, 43(5): 025332..

- 24.马辉*, 高昂, 杨天瑞, 官宏. 止口及螺栓对法兰盘结构静力学特性的影响[J]. 东北大学学报(自然科学版), 2022, 43(10): 1438-1444. .

- ************************2021年度(12篇SCI,14篇EI)************************.

- 1.Junzhe Lin,Tianrui Yang, Kaixuan Ni, Chenyi Han, Hui Ma*, Ang Gao, Chunliang Xiao. Effects of boundary conditions on stress distribution of hydraulic support: A simulation and experimental study [J]. Advances in Mechanical Engineering, 2021, 13(3): 1-16. 【SCI】.

- 2.Xu Li, Kangkang Chen, Yifan Huangfu, Hui Ma*, Baishun Zhao, Kun Yu. Vibration characteristic analysis of spur gear systems under tooth crack or fracture, Journal of Low Frequency Noise, Vibration and Active Control, 2021, 40(1): 135-153. 【SCI&EI】.

- 3.Hongzheng Han, Zhifang Zhao, Hongxu Tian, Hui Ma*, Yang Yang, Xu Li. Fault Feature analysis of planetary gear set influenced by cracked gear tooth and pass effect of the planet gears [J]. Engineering Failure Analysis, 2021, 121: 105162. 【SCI&EI】.

- 4.Jin Zeng, Chenguang Zhao, Hui Ma*, Xiaoli Cui, Wei Sun, Zhong Luo. Dynamic response characteristics of the shaft-blisk-casing system with blade-tip rubbing fault [J]. Engineering Failure Analysis, 2021, 125: 105406. 【SCI&EI】.

- 5.Kun Yu, Hui Ma*, Tianran Lin, Xu Li, Qiang Fu, Simulation data driven weakly supervised adversarial domain adaptation approach for intelligent cross-machine fault diagnosis, Structural Health Monitoring, 2021, 20(4): 2182–2198. 【SCI&EI】.

- 6.Zhifang Zhao, Hongzheng Han, Pengfei Wang, Hui Ma*, Shunhao Zhang, Yang Yang. An improved model for meshing characteristics analysis of spur gears considering fractal surface contact and friction [J]. Mechanism and Machine Theory, 2021, 158: 104219. 【SCI&EI】.

- 7.Kun Yu, Tianran Lin, Hui Ma*, Xiang Li, Xu Li. A multi-stage semi-supervised learning approach for intelligent fault diagnosis of rolling bearing using data augmentation and metric learning [J]. Mechanical Systems and Signal Processing, 2021, 146: 107043. 【SCI&EI】.

- 8.Xumin Guo, Kaixun Ni, Hui Ma*, Jin Zeng, Zelong Wang, Bangchun Wen. Dynamic response analysis of shrouded blades under impact-friction considering the influence of passive blade vibration [J]. Journal of Sound and Vibration, 2021, 503: 116112. 【SCI&EI】.

- 9.Hongyang Xu, Duo He, Hui Ma*, Kun Yu, Xiang Zhao, Yang Yang. A method for calculating radial time-varying stiffness of flexible cylindrical roller bearings with localized defects [J]. Engineering Failure Analysis, 2021, 128: 105590. 【SCI&EI】.

- 10.Yifan Huangfu, Jin Zeng, Hui Ma*, Dong Xingjian, Hongzheng Han, Zhifang Zhao. A flexible-helical-geared rotor dynamic model based on hybrid beam-shell elements [J]. Journal of Sound and Vibration, 2021, 511: 116361. 【SCI&EI】.

- 11.Xinxing Ma, Hui Ma*, Haiqin Qin, Xumin Guo, Chenguang Zhao, Mingyue Yu. Nonlinear vibration response characteristics of a dual-rotor-bearing system with squeeze film damper [J]. Chinese Journal of Aeronautics, 2021, 34(10): 128–147. 【SCI&EI】.

- 12.Junzhe Lin, Yulai Zhao, Pengfei Wang, Yuanyuan Wang, Qingkai Han, Hui Ma*, Nonlinear responses of a rotor-bearing-seal system with pedestal looseness [J]. Shock and Vibration, 2021, Volume 2021, Article ID 9937700, 22 pages. 【SCI&EI】.

- 13.赵百顺, 李 娜, 马辉*, 韩洪征, 赵志芳. 混合修形斜齿轮转子系统振动特性分析[J]. 振动工程学报, 2021, 34(4): 704-711. 【EI】.

- 14.马辉*, 于明月, 高昂, 赵晨光. 基于非线性虚拟材料栓接结合部动力学建模方法[J]. 东北大学学报(自然科学版), 2021, 42(8): 1111-1119. 【EI】.

- 15.韩晨怡, 倪凯旋, 马辉*, 王海, 林君哲. 约束边界和销轴简化对液压支架强度影响[J]. 哈尔滨工业大学学报, 2021, 53(1): 78-86. 【EI】.

- ************************2020年度(14篇SCI,18篇EI)************************.

- 1.Kun Yu, Hongzheng Han, Qiang Fu, Hui Ma*, Jin Zeng. Symmetric co-training based unsupervised domain adaptation approach for intelligent fault diagnosis of rolling bearing [J]. Measurement Science and Technology, 2020, 31: 115008. 【SCI&EI】.

- 2.Xumin Guo, Hui Ma*, Xufang Zhang, Zhuang Ye, Qiang Fu, Zhonghua Liu, Qingkai Han. Uncertain frequency responses of clamp-pipeline systems using an interval-based method [J]. IEEE Access, 2020, 8(1): 29370-29384. 【SCI&EI】.

- 3.Zhao Baishun, Huangfu Yifan, Hui Ma*, Zhifang Zhao, Kun Wang. The influence of the geometric eccentricity on the dynamic behaviors of helical gear systems [J]. Engineering Failure Analysis, 2020, 118: 104907. 【SCI&EI】.

- 4.Qingdong Chai, Jin Zeng, Hui Ma*, Kun Li. A dynamic modeling approach for nonlinear vibration analysis of the L-type pipeline system with clamps [J]. Chinese Journal of Aeronautics, 2020, 33(12): 3253–3265. 【SCI&EI】.

- 5.Kun Yu, Hui Ma*, Tianran Lin, Xiang Li. A consistency regularization based semi-supervised learning approach for intelligent fault diagnosis of rolling bearing [J]. Measurement, 2020, 165: 107987. 【SCI&EI】.

- 6.Jin Zeng, Chenguang Zhao, Hui Ma*, Bangchun Wen. Dynamic modeling and coupling characteristics of rotating inclined beams with twisted-shape sections [J]. Frontiers of Mechanical Engineering, 2020, 15(3): 374-389. 【SCI】.

- 7.Kun Yu, Hui Ma*, Jin Zeng, Hongzheng Han, Hongfei Li, Bangchun Wen. Frobenius and nuclear hybrid norm penalized robust principal component analysis for transient impulsive feature detection of rolling bearings [J]. ISA Transactions, 2020, 100: 373–386. 【SCI&EI】.

- 8.Kun Yu, Tian Ran Lin, Hui Ma*, Hongfei Li, Jin Zeng. A combined polynomial chirplet transform and synchroextracting technique for analyzing nonstationary signals of rotating machinery [J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(4): 1505-1518【SCI&EI】.

- 9.Xumin Guo, Jin Zeng, Hui Ma*, Chenguang Zhao, Lin Qu, Bangchun Wen. Dynamic characteristics of a shrouded blade with impact and friction, Frontiers of Mechanical Engineering, 2020, 15(2): 209-226. 【SCI&EI】.

- 10.Xumin Guo, Jin Zeng, Hui Ma*, Chenguang Zhao, Xi Yu, Bangchun Wen. A dynamic model for simulating rubbing between blade and flexible casing [J]. Journal of Sound and Vibration, 2020, 466: 115036. 【SCI&EI】.

- 11.Yifan Huangfu, Zhifang Zhao, Hui Ma*, Hongzheng Han, Kangkang Chen. Effects of tooth modifications on the dynamic characteristics of thin-rimmed gears under surface wear [J]. Mechanism and Machine Theory, 2020, 150: 103870. 【SCI&EI】.

- 12.Yifan Huangfu, Kangkang Chen, Hui Ma*, Xu Li, Hongzheng Han, Zhifang Zhao. Meshing and dynamic characteristics analysis of spalled gear systems: A theoretical and experimental study [J]. Mechanical Systems and Signal Processing, 2020, 139: 106640. 【SCI&EI】.

- 13.Xiang Li, Xu Li, Hui Ma*. Deep representation clustering-based fault diagnosis method with unsupervised data applied to rotating machinery [J]. Mechanical Systems and Signal Processing, 2020, 143: 106825. 【SCI&EI】.

- 14.Chenguang Zhao, Jin Zeng, Hui Ma*, Kaixuan Ni, Bangchun Wen. Dynamic analysis of cracked rotating blade using cracked beam element [J]. Results in Physics, 2020, 19: 103360. 【SCI&EI】.

- 15.马辉*,赵百顺,皇甫一樊,韩晨怡. 不对中工况下的修形齿轮副啮合特性分析[J]. 东北大学学报(自然科学版), 2020, 41(11): 1609-1614. 【EI】.

- 16.柴清东, 付强, 马辉*, 韩清凯, 张大志. 单-双联卡箍管路系统建模及动力学特性分析[J]. 振动与冲击, 2020, 39(19): 114-120. 【EI】.

- 17.李坤,曾劲,于明月,马辉,柴清东. 考虑螺栓连接刚度不确定性的带法兰-圆柱壳结构频响函数分析[J]. 振动工程学报, 2020, 33(3): 517-524. 【EI】.

- 18.马辉, 付强, 李坤, 樊富友. 考虑螺栓连接的吊挂式薄壁柱壳固有特性分析[J]. 东北大学学报(自然科学版),2020, 41(5): 686-692. 【EI】.

- 19.马辉, 李鸿飞, 俞昆, 曾劲. 含局部故障的滚动轴承动力学建模及振动分析[J]. 东北大学学报(自然科学版),2020, 41(3): 343-348. 【EI】.

- ***************************2019年度(3篇EI)***************************.

- 1.Hui Ma, Tong Yang, Shiyu Liu, Qi Sun, Bangchun Wen. Effects of twist angle on rubbing induced vibration responses of blade, International Conference on Rotor Dynamics, Mechanisms and Machine Sciences, 2019, 62: 193-204. 【EI】.

- 2.马辉*,崔璨,曾劲,闻邦椿. 考虑弹性支承的旋转凸肩叶片动力学特性分析[J]. 东北大学学报(自然科学版), 2019, 40(8): 1115-1121. 【EI】.

- 3.马辉*, 段田堂, 孙衍宁, 陈康康. 齿顶修形行星轮系啮合刚度分析[J]. 东北大学学报(自然科学版), 2019, 40(3): 380-385. 【EI】.

- ************************2018年度(4篇SCI,8篇EI)************************.

- 1.孙衍宁, 马辉*, 冯盟蛟, 等.变位直齿轮副齿顶修形参数设计[J]. 工程力学, 2018, 35(07): 243-248+256. 【EI】.

- 2.李炳强, 马辉*, 郝玉明, 谢方涛. 考虑机匣柔性的新型旋转叶片-机匣碰摩模型[J]. 东北大学学报(自然科学版), 2018, 39(8): 1143-1148. 【EI】.

- 3.Jin Zeng, Hui Ma*, Xinxing Ma, Zhiyuan Wu, Zhaoye Qin. Blade-loss-caused rubbing dynamic characteristics of rotor-bladed disk-casing system. Transactions of Nanjing University of Aeronautics and Astronautics, 2018, 35(1): 116-125. 【EI】.

- 4.Xinxing Ma, Hui Ma*, Jin Zeng, Yuhua Piao. Rubbing-induced vibration response analysis of dual-rotor-casing system. Transactions of Nanjing University of Aeronautics and Astronautics, 2018, 35(1): 102-108. 【EI】.

- 5.Mengjiao Feng, Hui Ma*, Zhanwei Li, Qibin Wang, Bangchun Wen. An improved analytical method for calculating time-varying mesh stiffness of helical gears [J]. Meccanica, 2018, 53: 1131-1145.【SCI&EI】.

- 6.Qi Sun, Hui Ma*, Yunpeng Zhu, Qingkai Han, Bangchun Wen, Comparison of rubbing induced vibration responses using varying-thickness-twisted shell and solid-element blade models [J], Mechanical Systems and Signal Processing, 2018, 108: 1-20. 【SCI&EI】.

- 7.Yanning Sun, Hui Ma*, Yifan Huangfu, Kangkang Chen, LinYang Che, Bangchun Wen, A revised time-varying mesh stiffness model of spur gear pairs with tooth modifications [J], Mechanism and Machine Theory, 2018, 129: 261-278. 【SCI&EI】.

- 8.Bingqiang Li, Hui Ma*, Jin Zeng, Xumin Guo, Bangchun Wen, Rotating blade-casing rubbing simulation considering casing flexibility, International Journal of Mechanical Sciences, 2018, 148: 118-134. 【SCI&EI】.

- *************************2017年度(3篇SCI,7篇EI)*************************.

- 1.Hui Ma*, Xinxing Ma, Qingkai Han, Bangchun Wen. Fault characteristic analysis of a rubbing rotor in the presence of pedestal looseness. International Journal of Smart Engineering, 2017, 1(1): 34-54..

- 2.Hui Ma*, Mengjiao Feng, Zhanwei Li, Ranjiao Feng, Bangchun Wen. Time-varying mesh characteristics of a spur gear pair considering the tip-fillet and friction. Meccanica, 2017, 52 (7): 1695-1709. 【SCI&EI】.

- 3.Hui Ma*, Xu Pang, Qibin Wang, Rongze Song, Bangchun Wen, Commentary on effects of tip relief on vibration responses of a geared rotor system, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2017, 23(11): 2159-2169. (ISSN: 0954-4062) 【SCI&EI】.

- 4.Hui Ma*, Di Wang, Xingyu Tai, Bangchun Wen, Vibration response analysis of blade-disk dovetail structure under blade tip rubbing condition, Journal of Vibration and Control, 2017, 23(2): 252-271. 【SCI&EI】.

- 5.马辉*, 孙祺, 太兴宇, 郝玉明, 闻邦椿. 旋转叶片-机匣碰摩振动响应分析[J]. 振动与冲击, 2017, 36(14): 26-31. 【EI】.

- 6.马辉*,武爽, 曾劲, 张文胜. 直裂纹悬臂梁系统阻尼特性分析[J]. 东北大学学报(自然科学版), 2017, 38(4): 546-550. 【EI】.

- 7.马辉*, 张文胜, 曾劲, 武爽. 非对称夹持的裂纹悬臂梁振动响应分析[J]. 振动与冲击, 2017, 36(12): 37-42. 【EI】.

- 8.马辉*, 孙帆, 殷帆丽, 王迪, 闻邦椿. 基于悬臂板理论的旋转叶片-机匣振动响应分析[J]. 振动工程学报, 2017, 30(2): 222-231. 【EI】.

- ************************2016年度(9篇SCI,11篇EI)************************.

- 1.Hui Ma*, Fanli Yin, Xingyu Tai, Di Wang, Bangchun Wen. Vibration response analysis caused by rubbing between rotating blade and casing, Journal of Mechanical Science and Technology, 2016, 30(5): 1983-1995. 【SCI&EI】.

- 2.Hui Ma*, Zhanwei Li, Mengjiao Feng, Ranjiao Feng, Bangchun Wen. Time-varying mesh stiffness calculation of spur gears with spalling defects, Engineering Failure Analysis, 2016, 66: 166-176. 【SCI&EI】.

- 3.Hui Ma*, Xu Pang, Ranjiao Feng, Bangchun Wen, Evaluation of optimum profile modification curves of profile shifted spur gears based on vibration responses, Mechanical Systems and Signal Processing, 2016, 70-71: 1131-1149. 【SCI&EI】.

- 4.Hui Ma*, Yang Lu, Zhiyuan Wu, Xingyu Tai, Bangchun Wen, Vibration response analysis of a rotational shaft-disk-blade system with blade-tip rubbing, International Journal of Mechanical Sciences, 2016, 107: 110-125. 【SCI&EI】.

- 5.Hui Ma*, Jin Zeng, Ranjiao Feng, Xu Pang, Bangchun Wen. An improved analytical method for mesh stiffness calculation of spur gears with tip relief, Mechanism and Machine Theory, 2016, 98: 64-80. 【SCI&EI】.

- 6.Hui Ma*, Jin Zeng, Ziqiang Lang, Long Zhang, Yuzhu Guo, Bangchun Wen. Analysis of the dynamic characteristics of a slant-cracked cantilever beam, Mechanical Systems and Signal Processing, 2016, 75: 261-279. 【SCI&EI】.

- 7.Hui Ma*, Fanli Yin, Yuzhu Guo, Xingyu Tai, Bangchun Wen. A review on dynamic characteristics of blade-casing rubbing, Nonlinear Dynamics, 2016, 84: 437-472. 【SCI&EI】.

- 8.Hui Ma*, Fanli Yin, Zhiyuan Wu, Xingyu Tai, Bangchun Wen. Non-linear vibration response analysis of a rotor-blade system with blade-tip rubbing, Nonlinear Dynamics, 2016, 84: 1225-1258. 【SCI&EI】.

- 9.Hui Ma*, Fangtao Xie,Haiqiang Nai, Bangchun Wen, Vibration characteristics analysis of rotating shrouded blades with impacts, Journal of Sound and Vibration, 2016, 378: 92-108. 【SCI&EI】.

- 10.马辉*, 王雪玲, 牛和强, 李辉. 升降速过程中转子系统油膜失稳规律, 振动、测试与诊断, 2016, 36(1): 56-61. 【EI】.

- 11.马辉*, 曾劲, 郎自强, 太兴宇. 斜裂纹悬臂梁非线性振动特性分析, 振动与冲击, 2016, 35(12): 86-91. 【EI】.

- ************************2015年度(10篇SCI,16篇EI)************************.

- 1.Hui Ma*, Zhiyuan Wu, Xingyu Tai, Chaofeng Li, Bangchun Wen. Nonlinear behavior analysis caused by blade tip rubbing in a rotor-disk-blade system, Proceedings of the 9th IFToMM International Conference on Rotor Dynamics, Mechanisms and Machine Science 21, 2015: 181-191. 【EI】.

- 2.Hui Ma*, Xingyu Tai, Qingkai Han, Zhiyuan Wu, Di Wang, Bangchun Wen, A revised model for rubbing between rotating blade and elastic casing, Journal of Sound and Vibration, 2015, 337: 301-320. 【SCI&EI】.

- 3.Hui Ma*, Xu Pang, Ranjiao Feng, Rongze Song, Bangchun Wen, Fault features analysis of cracked gear considering the effects of the extended tooth contact, Engineering Failure Analysis, 2015, 48: 105-120. 【SCI&EI】.

- 4.Xingyu Tai, Hui Ma*, Fuhao Liu, Yang Liu, BangchunWen, Stability and steady-state response analysis of a single rub-impact rotor system, Archive of Applied Mechanics, 2015, 85:133-148. 【SCI&EI】.

- 5.Hui Ma*,Qianbin Zhao, Xueyan Zhao, Qingkai Han, Bangchun Wen, Dynamic characteristics analysis of a rotor-stator system under different rubbing forms, Applied Mathematical Modelling, 2015, 39(8): 2392-2408. 【SCI&EI】.

- 6.Hui Ma*, Xueling Wang, Heqiang Niu, Bangchun Wen, Oil-film instability simulation in an overhung rotor system with flexible coupling misalignment, Archive of Applied Mechanics, 2015, 85 (7): 893-907. 【SCI&EI】.

- 7.Hui Ma*, Xu Pang, Jin Zeng, Qibin Wang, Bangchun Wen. Effects of gear crack propagation paths on vibration responses of the perforated gear system. Mechanical Systems and Signal Processing, 2015, 62-63: 113-128. 【SCI&EI】.

- 8.Hui Ma*, Jin Zeng, Ranjiao Feng, Xu Pang, Qibin Wang, Bangchun Wen. Review on dynamics of cracked gear systems, Engineering Failure Analysis, 2015, 55: 224-245. 【SCI&EI】.

- 9.Hui Ma*, Xu Pang, Ranjiao Feng, Jin Zeng, Bangchun Wen. Improved time-varying mesh stiffness model of cracked spur gears, Engineering Failure Analysis, 2015, 55: 271-287. 【SCI&EI】】.

- 10.Hui Ma*, Ranjiao Feng, Xu Pang, Rongze Song, Bangchun Wen. Effects of tooth crack on vibration responses of a profile shifted gear rotor system, Journal of Mechanical Science and Technology, 2015, 29(10): 4093-4104. 【SCI& EI】.

- 11.Hui Ma*, Yang Lu, Zhiyuan Wu, Xingyu Tai, Hui Li, Bangchun Wen. A new dynamic model of rotor-blade systems, Journal of Sound and Vibration, 2015, 357: 168-194. 【SCI&EI】.

- 12.马辉*, 王迪, 能海强, 太兴宇. 压气机盘片榫连结构接触特性分析, 东北大学学报(自然科学版), 2015, 36(1): 109-113. 【EI】.

- 13.马辉*, 逄旭, 宋溶泽, 闻邦椿. 考虑齿轮-转子系统振动响应的最佳修形曲线研究, 振动与冲击, 2015, 34 (11): 17-22. 【EI】.

- 14.马辉*, 吴志渊, 太兴宇, 闻邦椿. 含碰摩故障的转子-盘片-机匣系统动力学特性分析. 航空动力学报, 2015, 30(8): 1950-1957.【EI】.

- 15.马辉*, 王迪, 太兴宇, 能海强, 闻邦椿. 碰摩作用下盘片榫连结构接触特性的响应分析. 航空动力学报, 2015, 30 (9): 2203-2211. 【EI】.

- 16.马辉*, 曾劲, 吴志渊, 秦朝烨. 基于LS-DYNA模拟碰撞诱发的裂纹扩展. 东北大学学报(自然科学版), 2015, 36(11): 1653-1657. 【EI】.

- ************************2014年度(6篇SCI,10篇EI)************************.

- 1.Hui Ma*, Jian Yang, Rongze Song, Suyan Zhang, Bangchun Wen, Effects of tip relief on vibration responses of a geared rotor system, Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 2014, 228(7): 1132-1154. 【SCI&EI】.

- 2.Hui Ma*, Hui Li, Heqiang Niu, Rongze Song, BangchunWen. Numerical and experimental analysis of the first and second-mode instability in a rotor-bearing system. Archive of Applied Mechanics, 2014, 84(4): 519-541. 【SCI&EI】.

- 3.Hui Ma*, Rongze Song, Xu Pang, Bangchun Wen. Time-varying mesh stiffness calculation of cracked spur gears, Engineering Failure Analysis, 2014, 44: 179-194. 【SCI&EI】.

- 4.Hui Ma*, Rongze Song, Xu Pang, Bangchun Wen. Fault feature analysis of a cracked gear coupled rotor system, Mathematical Problems in Engineering, Volume 2014, Article ID 832192, 22 pages. 【SCI&EI】.

- 5.Hui Ma*, Zhiyuan Wu, XingyuTai, Bangchun Wen, Dynamic characteristics analysis of a rotor system with two types of limiters, International Journal of Mechanical Sciences, 2014, 88: 192-201. 【SCI&EI】.

- 6.Hui Ma*, Xueling Wang, Heqiang Niu, Hui Li, Effects of different disc locations on oil-film instability in a rotor system, Journal of Vibroengineering, 2014, 16 (7):3248-3259. 【SCI&EI】.

- 7.马辉*, 逄旭, 宋溶泽, 杨健. 基于改进能量法的直齿轮时变啮合刚度计算, 东北大学学报(自然科学版), 2014, 35(6): 863-866. 【EI】.

- 8.马辉*,杨健,宋溶泽,能海强,闻邦椿. 转子系统碰摩故障实验研究进展与展望. 振动与冲击, 2014, 33(6): 1-12. 【EI】.

- 9.马辉*,逄旭,宋溶泽,杨健,张素燕. 考虑齿顶修缘的齿轮-转子系统振动响应分析. 机械工程学报, 2014, 50(7): 39-45. 【EI】.

- 10.马辉*, 王奇斌, 黄婧, 张义民, 不同自由度耦合斜齿轮转子系统的振动特性, 振动、测试与诊断, 2014, 34(4): 650-657. 【EI】.

- ************************2013年度(5篇SCI,15篇EI)************************.

- 1.Hui Ma*, Jing Huang, Suyan Zhang, Heqiang Niu. Nonlinear vibration characteristics of a rotor system with pedestal looseness fault under different loading conditions. Journal of Vibroengineering, 2013, 15(1): 406-418. 【SCI&EI】.

- 2.Hui Ma*, Chaoyang Shi, Qingkai Han, Bangchun Wen. Fixed-point rubbing fault characteristic analysis of a rotor system based on contact theory. Mechanical Systems and Signal Processing, 2013, 38(1): 137-153. 【SCI&EI】.

- 3.Hui Ma*, Hui Li, Heqiang Niu, Rongze Song, Bangchun Wen. Nonlinear dynamic analysis of a rotor-bearing -seal system under two loading conditions, Journal of Sound and Vibration, 2013, 332(23): 6128-6154. 【SCI&EI】.

- 4.Hui Ma*, Hui Li, Xueyan Zhao, Heqiang Niu, Bangchun Wen. Effects of eccentric phase difference between two discs on oil-film instability in a rotor-bearing system. Mechanical Systems and Signal Processing, 2013, 41(1-2): 526– 545. 【SCI&EI】.

- 5.Hui Ma*, Xingyu Tai, Heqiang Niu, Rongze Song. Numerical research on rub-impact fault in a blade-rotor-casing coupling system. Journal of Vibroengineering, 2013, 15(3): 1477-1489. 【SCI&EI】.

- 6.马辉*, 李辉, 牛和强, 能海强. 两种转子-轴承系统模型的油膜失稳故障仿真, 中国工程机械学报, 2013, 11(4): 340-346. .

- 7.马辉*, 能海强, 吕颂, 宋溶泽. 变厚度壳单元的旋转叶片振动响应分析, 机械设计与制造, 2013, 11: 109-112..

- 8.马辉*,能海强,宋溶泽,张志,闻邦椿. 基于变厚度壳单元的旋转叶片固有特性分析, 航空发动机, 2013, 39(5): 26-30..

- 9.马辉*,王奇斌,黄婧,张义民. 考虑几何偏心的斜齿轮耦合转子系统振动响应分析. 航空动力学报,2013, 28(1): 16-24. 【EI】.

- 10.马辉*,太兴宇,张志,闻邦椿. 根部联接刚度对旋转叶片振动特性的影响. 东北大学学报(自然科学版),2013, 34(2):265-270. 【EI】.

- 11.马辉*,汪博,太兴宇,闻邦椿. 基于接触分析的转定子系统整周碰摩故障模拟. 工程力学,2013, 30(2): 365-371. 【EI】.

- 12.马辉*,李辉,唐玉生,闻邦椿. 两种不同载荷形式下转子系统油膜失稳的数值研究. 振动工程学报,2013, 26(1): 105-111. 【EI】 .

- 13.马辉*, 太兴宇, 牛和强, 闻邦椿. 转定子静态不对中条件下碰摩故障仿真. 振动工程学报, 2013,26(2): 260-268. 【EI】.

- 14.马辉*, 李辉, 张素燕, 闻邦椿. 转子系统二阶油膜失稳故障仿真及试验研究. 机械工程学报, 2013, 49(9): 24-29. 【EI】.

- 16.马辉*, 吕颂, 能海强, 宋溶泽. 转定子系统整周多点碰摩故障仿真. 东北大学学报(自然科学版), 2013, 34(8): 1149-1153. 【EI】.

- 16.马辉*, 太兴宇, 李焕军, 闻邦椿. 旋转叶片-机匣碰摩模型及试验研究综述. 航空动力学报, 2013, 28(9): 2055-2069. 【EI】.

- 17.马辉*, 能海强, 宋溶泽, 唐玉生. 两种工况下锻压组合机架的接触特性分析, 东北大学学报(自然科学版),2013, 34(9): 1300-1304. 【EI】.

- 18.马辉*,李辉,牛和强,闻邦椿. 滑动轴承-转子系统油膜失稳参数影响分析, 振动与冲击, 2013, 32(23): 100-104. 【EI】.

- ************************2012年度(1篇SCI,5篇EI)************************.

- 1.Hui Ma*, Xingyu Tai, Zhi Zhang, Bangchun Wen. Dynamic characteristic analysis of a rotor system with rub-impact fault considering rotor-stator misalignment, Przeglad Elektrotechniczny, 2012, 88(9B): 145-149.【SCI】.

- 2.Hui Ma*, Hao Zuo , Xingyu Tai and Bangchun Wen. Comparison of critical speeds of a rotor system with different types of finite elements. Advanced Engineering Forum Vols. 2-3 (2012) pp 711-716.

- 3.马辉*,惠洪杰,唐玉生,张素燕,闻邦椿. 振动与冲击,2012,31(S):40-43..

- 4.马辉*,孙健,张素燕. 压缩机组不对中故障动力学特性分析. 中国科技论文在线.

- 5.马辉*,太兴宇,李辉. 基于Hertz接触碰摩模型的转子系统振动响应分析. 中国科技论文在线精品论文, 2012, 5(16): 1492-1498..

- 6.马辉*,太兴宇,汪博,闻邦椿. 柔性转子系统轮盘外缘定点碰摩动力学特性分析. 中国电机工程学报, 2012, 32(17): 89-96. 【EI】.

- 7.马辉*,李焕军,刘杨,闻邦椿. 转子系统耦合故障研究进展与展望. 振动与冲击, 2012, 31(17): 1-11.【EI】.

- 8.马辉*,张志,太兴宇,闻邦椿. 不同载荷下基座松动转子系统动力学特性分析. 中国电机工程学报, 2012, 32(26): 132-137. 【EI】.

- 9.马辉*,太兴宇,汪博,闻邦椿. 松动-碰摩耦合故障转子系统动力学特性分析. 机械工程学报, 2012, 48(19): 80-86. 【EI】.

- 10.马辉*,朱丽莎,王奇斌,张义民. 斜齿轮-平行轴转子系统模态耦合特性分析. 中国电机工程学报, 2012, 32(29): 131-136. 【EI】.

- ************************2011年度(2篇SCI,1篇EI)************************.

- 1.Hui Ma*, Xingyu Tai, Jian Sun, Bangchun Wen. Analysis of dynamic characteristics for a dual-disk rotor system with single rub-impact, Advanced Science Letters, 2011, 4(8-10): 2782-2789. 【SCI】.

- 2.Hui Ma*, Xueyan Zhao, Yunnan Teng and Bangchun Wen. Analysis of dynamic characteristics for a rotor system with pedestal looseness. Shock and Vibration, 2011, 18(1-2): 13-27.【SCI&EI】.

- 3.马辉*, 陈雪莲,李朝峰,闻邦椿. 基于关联维数和小波分析的转子系统碰摩故障分析.机械强度,2011,33(1):148-151.

- *************************2010年度(4篇EI)*************************.

- 1.Hui Ma*, Zhaohui Ren, Jishuang Dai, Bangchun Wen. Research on Dynamics of Rotor Systems in Large Centrifugal Compressor. Key Engineering Materials, 2010, 419-420: 121-124 【EI】.

- 2.Hui Ma* , Yunnan Teng , Jishuang Dai and Bangchun Wen. Bearing Parameter Optimization of a Compressor Rotor System Based on Orthogonal Experimental Design. Advanced Materials Research Vols. 118-120 (2010) pp. 394-398. 【EI】.

- 3.马辉*, 戴继双, 孟磊, 闻邦椿. 大型离心压缩机转子系统不平衡响应分析, 中国工程机械学报, 2010, 8(2): 127-131..

- 4.马辉*, 李朝峰, 轩广进, 闻邦椿. 转子油膜失稳故障的时频特征分析. 振动与冲击, 2010, 29(2):193-195. 【EI】.

- 5.马辉*, 孙伟, 戴继双, 闻邦椿. 基于正交试验的大型离心压缩机轴承参数优化.计算机集成制造系统, 2010, 16(2): 390-395. 【EI】.

- ************************2009年度(1篇SCI,5篇EI)************************.

- 1.Hui Ma*, Jishuang Dai, Xuejun Wang and Bangchun Wen. Dynamics analysis of Rotor Systems in Large Centrifugal Compressor, Applied Mechanics and Materials, 2009,16-19:115-119【EI】.

- 2.Hui Ma*, Tao Yu, Qingkai Han, Yimin Zhang, Bangchun Wen, Xuelian Chen. Time-frequency features of two types of coupled rub-impact faults in rotor systems. Journal of Sound and Vibration, 2009, 321(3-5): 1109-1128【SCI& EI】.

- 3.马辉*, 孙伟, 任朝晖, 闻邦椿. 多盘悬臂转子系统支座松动故障研究. 航空动力学报, 2009,24(7):1512-1517. 【EI】.

- 4.马辉*, 陈雪莲, 滕云楠, 闻邦椿. 转子系统碰摩故障分岔特性的实验研究. 仪器仪表学报,2009,30(9):1808-1812. 【EI】.

- 5.马辉*, 孙伟, 王学军, 闻邦椿. 转子系统松动故障特征分析. 东北大学学报(自然科学版),2009,30(3):400-404【EI】.

- ************************2007年度(5篇EI)************************.

- 1.马辉*,陈雪莲,王凯,闻邦椿.油膜振荡引起的轴承碰摩故障研究. 东北大学学报(自然科学版),2007,28(9):1313-1316【EI】.

- 2.马辉*, 孙伟, 刘杰, 闻邦椿. 旋转机械支座松动故障的实验. 农业机械学报,2007,38(6):134-137 【EI】.

- 3.马辉*, 孟磊, 刘杰, 闻邦椿. 时频分析在油膜失稳与局部碰摩耦合故障中的应用. 机械强度,2007,29(5):699-703 【EI】.

- 4.马辉*, 赵群超, 宋雪萍, 闻邦椿. 基于重分配小波尺度图的转子系统支座松动故障的研究. 中国机械工程, 2007, 18(8): 962-966 【EI】.

- 5.马辉*, 赵鑫, 赵群超, 闻邦椿. 时频分析在旋转机械故障诊断中的应用. 振动与冲击, 2007, 26(3): 61-63【EI】.

- ************************2006年度(1篇EI)************************.

- 1.马辉*, 周文建, 闻邦椿. 核电站反应堆冷却剂泵的模态分析. 机械制造.

- 2.马辉*, 宋雪萍, 赵鑫, 闻邦椿. 小波包分析在转子裂纹故障检测中的应用. 振动、测试与诊断【EI】.

- ******************************************************************.

专利

- 获批的日本专利(第1申请人):

- 1. 马辉,罗忠,韩清凯,孙伟,李晖,李朝峰,姜世杰,李鹤,任朝晖,闻邦椿. 螺栓松动下纤维增强复合盘鼓薄壁构件旋转振动试验台[P]. 日本,专利号:特许第6863627号,2021/4/5. (专利申请号:PCT/CN2017/118855,申请日期:2017/12/27).

- 获批的专利(第1申请人):

- 【叶片类专利,转子/叶片17个专利】

- 2. 马辉,太兴宇,李朝峰,闻邦椿. 旋转叶片-机匣碰摩力的确定方法[P]. 中国:专利号: ZL 201310482755.5, 2016/4/20.(专利申请号 201310482755.5,申请日期: 2013/10/16)

- 3. 马辉,太兴宇,吴志渊,闻邦椿. 一种转子-叶片耦合系统固有频率的确定方法[P]. 中国:专利号: ZL 201410384747.1, 2017/3/22. (申请日期:2014/08/07,申请号:201410384747.1)

- 4. 马辉,李炳强,郭旭民,孙帆,谢方涛,孙祺,崔璨. 一种改进的旋转叶片-柔性机匣碰摩力确定方法[P]. 中国:专利号: ZL201710268588.2, 2019/12/03 (申请号:201710268588.2,申请日期:2017/4/24)

- 5. 马辉,曾劲,张文胜,闻邦椿. 一种航空发动机叶片裂纹预测方法[P]. 中国, 专利号: ZL201710019243.3,2020/2/14.(申请号: 201710019243.3,申请日期2017/1/11)

- 6. 马辉,孙帆,谢方涛,孙祺,崔璨,郭旭民. 一种基于安装角的扭形叶片动力学建模方法[P]. 专利号: ZL201710264255.2,2020/7/24.(专利申请号201710264255.2,申请日期:2017/4/24)

- 7. 马辉,崔璨,杨桐,刘诗宇,曾劲,郭旭民. 基于变截面梁的弹性支承下扭形凸肩叶片动力学建模方法[P]. 中国:ZL201810692396.9,2020/9/15. (专利申请号201810692396.9,申请日期:2018/6/28)

- 8. 马辉,刘诗宇,崔璨,曾劲,杨桐. 一种弹簧-变截面盘-叶片系统的动力学建模方法[P]. 中国:ZL201810812237.8,2020/9/15. (专利申请号201810812237.8. 申请日期:2018/7/23)

- 9. 马辉,刘诗宇,崔璨,曾劲,杨桐. 旋转圆柱壳-变截面盘-预扭叶片系统的动力学建模方法[P]. 中国:ZL201910064646.9,2020/11/10. (专利申请号201910064646.9. 申请日期:2019/1/23)

- 10. 马辉,李坤,孟春晓. 一种螺栓连接鼓筒转子结构的响应特性分析方法[P]. 中国: ZL 201810575154.1,2020/8/28. (专利申请号201810575154.1,申请日期:2018/6/6)

- 11. 马辉,李坤,付强,柴清东. 螺栓连接带法兰的圆柱壳结构频响函数不确定性分析方法 [P]. 中国:ZL 201910153530.2,2022/9/30. (专利申请号201910153530.2,申请日期:2019/2/28)

- 12. 马辉,李坤,于明月. 一种旋转圆柱壳动力学特性不确定性分析方法 [P]. 中国:ZL 201910719892.3,2022/11/18.(专利申请号201910719892.3,申请日期:2019/8/6)

- 13. 马辉,赵晨光,曾劲,李朝峰,张学良. 一种叶片和机匣系统在碰摩故障下的力学特性分析方法 [P]. 中国:ZL 201910883150.4,2022/12/2. (专利申请号201910883150.4,申请日期:2019/09/18)

- 14. 马辉, 付强, 于明月, 李坤. 一种基于螺栓连接的吊挂式薄壁柱壳固有特性分析方法 [P]. 中国:ZL 201910286265.5,2022/12/13. (专利申请号201910286265.5,申请日期:2019/04/10)

- 15. 马辉, 曾劲, 赵晨光. 一种机械结构在基础激励下的响应特性分析方法 [P]. 中国:ZL 201910546452.2,2023/3/24.(专利申请号201910546452.2,申请日期:2019/06/18)

- 16. 马辉, 郭旭民, 曾劲, 罗忠, 李朝峰. 一种叶片-机匣碰摩关系的确定方法 [P]. 中国:ZL 201910878227.9,2023/3/24. (专利申请号201910878227.9,申请日期:2019/09/17).

- 17. 马辉, 杨桐, 马新星, 崔璨, 曾劲, 郭旭民. 一种基于阶梯轴-柔性盘耦合系统的动力学建模方法 [P]. 中国:ZL 201811515829.X,2023/4/7.(专利申请号:201811515829.X,申请日期:2018/12/12)

- 18. 马辉,杨天瑞,李朝峰,孙伟,韩清凯,罗忠. 一种适用于圆柱壳结构的碰摩力预测方法[P]. 中国:ZL 202111285078.9,2024/05/28.(专利申请号:202111285078.9,申请日期:2021/11/01)

- 【齿轮类专利,11个专利】

- 19. 马辉,冯然娇,逄旭,闻邦椿. 一种考虑延长啮合的裂纹齿轮转子系统动力参数确定方法[P]. 专利号: ZL 201510250508.1, 2017/12/5.(申请号201510250508.1,申请日期:2015.05.18)

- 20. 马辉,孙衍宁,冯盟蛟, 李占伟,段田堂. 一种修正的考虑鼓向修形的齿轮副啮合特性分析方法[P]. 中国:专利号: ZL 201710329619.0, 2019/7/19.(申请号:201710329619.0 申请日期:2017/5/11)【专利转让34万】

- 21. 马辉,段田堂,李占伟,闻邦椿. 一种考虑基体裂纹影响的齿轮啮合特性有限元分析方法[P]. 中国, 专利号: ZL 201710632301.X, 2020/4/14. (申请号:201710632301.X,申请日期:2017/7/28))【专利转让100万】

- 22. 马辉, 陈康康, 李占伟, 闻邦椿, 张学良.考虑基体刚度修正的剥落斜齿轮副的啮合特性分析方法[P]. 中国, 专利号: ZL 201710624808.0, 2020/4/14.(申请号:201710624808.0,申请日期:2017/7/27)

- 23. 马辉,皇甫一樊,陈康康,孙衍宁,闻邦椿. 一种齿轮副啮合特性分析方法[P].专利号: ZL201810574318.9,2020/7/28. (专利申请号201810574318.9,申请日期:2018/6/6)

- 24. 马辉, 皇甫一樊, 陈康康,李娜,赵百顺. 一种基于动态啮合力的齿轮副磨损量预测方法[P]. 专利号:ZL 201910195352.X,2022/10/04.(专利申请号201910195352.X,申请日期:2019/3/14)【专利转让105万】

- 25. 马辉, 陈康康,皇甫一樊, 赵志芳, 韩洪征. 考虑复杂基体与裂纹扩展路径的直齿轮啮合刚度计算方法[P]. 专利号:ZL 201910105658.1,2022/12/30. (专利申请号201910105658.1,申请日期:2019/2/1)

- 26. 马辉, 王昆, 曹海军, 吴宏登, 罗方, 陈康康, 皇甫一樊, 李娜. 考虑延长啮合和齿圈柔性的内啮合齿轮副啮合刚度计算方法[P]. 专利号: ZL 201910303911.4, 2023/1/24. (专利申请号201910303911.4,申请日期:2019/4/16). 注:【专利权人:江苏省金象传动设备股份有限公司】

- 27. 马辉,韩洪征,赵志芳,田洪旭,王鹏飞. 基于边频分布规律的行星轮轮齿裂纹故障特征判定方法 [P]. 专利号:ZL 202110837913.9,2023/09/22.(专利申请号202110837913.9,申请日期2021/7/23).

- 28. 马辉, 王昆, 吴宏登, 皇甫一樊, 罗方, 毛广春, 高军, 刘年. 薄轮缘齿轮系统固有特性及节径振动预估方法 [P]. 专利号:ZL 202010743034.5,2023/09/26.(专利申请号202010743034.5,申请日期2020/7/29)注:【专利权人:江苏省金象传动设备股份有限公司】

- 29. 马辉, 王昆, 曹海军, 吴宏登, 罗方, 陈康康, 皇甫一樊, 李娜. 考虑齿轮不对中与齿面偏载的齿轮疲劳试验机 [P]. 专利号:ZL 201910105400.1,2023/09/26.(专利申请号201910105400.1,申请日期2019/2/1)注:【专利权人:江苏省金象传动设备股份有限公司】

- 【故障诊断及信号处理专利,4个专利】

- 30. 马辉,俞昆,付强,曾劲. 基于矩阵恢复的滚动轴承微弱故障增强方法[P]. 中国,专利号: ZL 201910647394.2,2020/5/12.(申请号:201910647394.2, 申请日期:2019/7/18)

- 31. 马辉,李鸿飞,俞昆,曾劲,罗志涛. 基于广义线性调频双同步提取变换的非平稳信号处理方法[P]. 中国,专利号: ZL201810800356.1,2021/10/1. (申请号:201810800356.1, 申请日期:2018/7/20)

- 32. 马辉,俞昆,杨阳,罗忠,李旭,李响. 一种强频变信号时频分析方法[P]. 中国:专利号ZL 202011003461.6,2024/01/26(申请日期 2020/09/22)

- 33. 马辉,俞昆,杨阳,罗忠,李旭,李响. 仿真数据驱动的旋转机械深度半监督迁移诊断方法[P]. 中国:专利号ZL 202011002774.X,2024-02-20(申请日期 2020-09-22)

- 【轴承相关专利,4个专利】

- 34. 马辉,徐宏阳,赵翔,王鹏飞,贺多. 一种联合载荷作用下的球轴承极限承载能力计算方法[P]. 中国:专利号ZL 202110870702.5,2023/08/04 (申请日期2021年7月30日)

- 35. 马辉,徐宏阳,赵翔,俞昆,贺多,杨阳,罗忠,李旭,李响. 一种计算柔性圆柱滚子轴承时变刚度的解析-有限元方法[P]. 中国:专利号ZL 202011427157.4,2024-02-13(申请日期 2020/12/9)

- 36. 马辉,徐宏阳,赵翔,王鹏飞,贺多,杨阳. 一种含组合角不对中的深沟球轴承准静态解析模型分析方法[P]. 中国:专利号ZL202111208395.0,2024-05-17(申请日期 2021/10/18)

- 37. 马辉,徐宏阳,佟雪,赵翔,李旭,罗忠,韩清凯,李小彭. 一种花键连接齿轮转子系统中含不对中轴承刚度计算方法 [P]. 中国:专利号ZL 202210567154.3,2025-04-18(申请日期2022-05-23)

- 【管路类专利,9个专利】

- 38. 马辉, 柴清东, 朴玉华, 李坤. 一种卡箍-管路系统动力学建模的方法 [P]. 中国,专利号: ZL201811631405.X,2023/2/24. (申请号:201811631405.X,申请日期: 2018/12/29).

- 39. 马辉, 柴清东, 朴玉华, 吴文轩. 一种考虑螺栓连接的航发管路建模及振动特性分析方法 [P]. 中国, 申请号:ZL 201910228529.1, 2023/1/13. (申请号:201910228529.1,申请日期:2019/03/25).

- 40. 马辉, 付强, 肖春亮, 柴清东, 林君哲. 一种能够夹持任意空间复杂管路的夹具装置[P]. 中国,专利号: ZL2019 1091 3243.7,2022/6/21. (申请号:2019 1091 3243.7, 申请日期:2019/9/25)

- 41. 马辉, 陆鹏旭, 邹泽煜, 徐鹤松, 闫兴华, 李丹丹, 张郡纹, 高智江, 胡晓岳, 孙伟, 汪博, 韩清凯, 李晖, 王梓澎, 张铭宇. 一种具有减振耐温功能的航空发动机双联卡箍[P]. 中国, 专利号:ZL 202110811180.1,2022/9/6. (申请号:202110811180.1,申请日期:2021/7/19)

- 42. 马辉, 柴清东, 付强, 李坤. 一种L型管路卡箍系统建模的方法 [P]. 中国, 专利号:ZL 201910586155.0,2022/11/18. (申请号:201910586155.0,申请日期:2019/7/1)

- 43. 马辉, 郭旭民, 曾劲, 罗忠, 李朝峰. 一种卡箍-管路系统频响函数的不确定性分析方法[P]. 中国, 专利号:ZL201910867151.X, 2022/11/18. (申请号:201910867151.X,申请日期:2019/9/12)

- 44. 马辉, 柴清东, 李坤, 付强. 一种单双联卡箍管路系统建模的方法 [P]. 中国, 专利号:ZL 2019 1058 6153.1, 2022/12/13. (申请号:2019 1058 6153.1,申请日期:2019/07/01)

- 45. 马辉,付强,刘守华,肖春亮,葛寒,刘中华. 一种单联金属毡卡箍刚度的建模方法[P]. 中国, 专利号:ZL 202011473964.X, 2024/2/2.(申请号:202011473964.X,申请日期:2020/12/15).

- 46. 马辉,曹一明,郭旭民,葛寒,孙伟,李晖,汪博,张让威,高东武,林君哲,韩清凯. 一种带连接软管的输流管路的建模方法[P]. 专利申请号: 202211098306.6, 申请日期:2022年9月8日. 【申请人:东北大学,中国航发沈阳发动机研究所】 【待授权】

著作成果

- 1. 闻邦椿, 李小彭, 李鹤, 马辉. 机械产品设计质量的检验与评估[M]. 北京:机械工业出版社, 22万字,2010

- 2. 马辉, 闻邦椿, 太兴宇, 韩清凯. 旋转叶片-机匣系统碰摩动力学[M]. 北京:科学出版社, 30.9万字,2017

- 3. 马辉, 韩清凯, 太兴宇, 闻邦椿. 转子系统动力学基础与数值仿真[M]. 武汉:武汉理工大学出版社, 39.7万字,2018

- 4. 李鹤, 马辉, 李朝峰, 刘杨. 机械系统动力学[M]. 武汉:华中科技大学出版社, 34.2万字,2021

- 5. 马辉, 孙伟, 郭旭民, 徐昆鹏. ANSYS结构力学分析及工程应用实例[M]. 沈阳: 东北大学出版社, 54.9万字, 2024.

科研项目

- (46) 2025年,中国飞机强度研究所,转静子碰摩细观特征与耦合动力学响应测试与分析研究,2025.6.10-2026.10.30,15万,在研,主持。

- (45) 2024年,广东省基础与应用基础研究基金项目—海上风电联合基金(面上项目),内外联合激励下海上风力发电机传动系统齿面失效机理及寿命预测技术,2024.11.1-2027.10.31,30万,在研,主持。

- (44) 2024年,沈阳市科技计划项目,叶片多尺度裂纹动态扩展与非线性振动机理研究,2024.7.1-2027.6.30,40万,在研,主持。

- (43) 2024年,北京航星测通科技有限公司横向项目,某传动系统动力学建模及振动特征分析研究,2024.4.28-2024.12.31,40万,在研,主持。

- (42) 2023年,两机专项课题,整机力学建模方法及部件间隙设计方法研究,2023.9.1-2025.6.30,398万,在研,主持。

- (41) 2023年,航空科学基金项目,转静子耦合系统碰摩机理及故障特征提取技术研究(20230015050001),2023.10-2025.9,18万,在研,主持。

- (40) 2023年,中国航发沈阳黎明航空发动机有限责任公司,管路卡箍金属橡胶性能衰减研究,2023.11.16-2024.11.16,27.57万,在研,主持。

- (39) 2023年,上海浏青科技有限公司专利实施许可项目,一种基于动态啮合力的齿轮副磨损量预测方法,2023.5.30-2026.5.29,105万,在研,主持。

- (38) 2023年, 中国航发四川燃气涡轮研究院横向委托课题(JSYJ-2023-0004),复杂工况下故障齿轮系统动力学响应、齿轮性能退化过程定量分析及原理级试验验证技术研究,2023.1-2023.12,110万,在研,主持。

- (37) 2022年,中国船舶重工集团公司第703所横向委托课题,考虑安装及运行环境的传动系统故障特征提取、诊断与寿命预测,2022.12-2023.9,61万,在研,主持。

- (36) 2022年,北京新典恒益科技有限公司专利实施许可项目,一种考虑基体裂纹影响的齿轮啮合特性有限元分析方法(ZL 201710632301.X),2022.11-2025.11,100万,在研,主持。

- (35) 2022年,首批辽宁省高等学校“揭榜挂帅”项目(LNJYT-02),航空动力装备高功率密度传动系统低振动设计与知识组件技术,2022.1-2023.12, 20万,在研,主持。

- (34) 2022年,直升机传动技术重点实验室开放课题项目,直升机主传动系统典型故障动力学及特征演变规律研究(HTL-0-21G03),2022.1-2023.12,9万,在研,主持。

- (33) 2021年,教育部基本业务费国防预研项目(国防重大培育项目),XX齿轮传动系统典型故障动力学及故障特征提取(N2103024),2021.1-2023.12,25万,在研,主持。

- (32) 2021年,中国航发沈阳发动机研究所,星型传动-转子耦合系统建模与动力学分析(2021JX04H006),2021.1-2021.12,58万,在研,主持。

- (31) 2020年,两机专项项目课题(2021JX08LJZX03),航空发动机外部结构振动传递特性、主被动控制与寿命试验方法研究,2020.1-2023.12,1144万,在研,主持。

- (30) 2020年,清华大学为外委课题,2020JX11H001,2020.9-2021.6,20万,在研,主持。

- (29) 2020年,国家重点研发计划课题(2020YFB2007802),轴承疲劳磨损与轴电流损伤机理,2020.10-2023.09,196万,在研,主持。

- (28) 2020年,江苏金象传动设备股份有限公司,专利实施许可,一种修正的考虑鼓向修形的齿轮副啮合特性分析方法,2020.8-2023.7,34万,在研,主持。

- (27) 2020年,中国航发湖南动力机械研究所(608所)两机专项外协项目,行星传动故障特征提取方法研究及验证(2020JX04H012),2020.8-2020.10,130万,在研,已结题。

- (26) 2020年,国防科工局重大工程项目子课题(与201所联合申请,2021JX02GC01),基于多源激励振动信号的传动状态感知识别方法,2020.1-2022.12,220万,在研,主持。

- (25) 2020年,中国船舶重工集团公司第703所横向委托课题,传动装置典型振动故障机理分析(2020JX04H001),2020.5-2021.3,76万,主持。

- (24) 2022年,项目名称:齿轮传动系统动力学及典型故障特征提取关键技术与应用(项目编号:N2003014),经费来源:教育部项目基本科研业务费项目—基地成果项目,起止年月:2020年1月-2021年12月,经费额度12万,主持。

- (23) 2020年,项目名称:含裂纹转子叶片动力学建模及非线性振动特性研究 (项目编号:11972112),经费来源:国家自然科学基金委,起止年月:2020年1月-2023年12月,直接经费额度63万,主持。

- (22) 2019年,项目名称:起重机新型主梁结构的刚度、强度及变形分析计算(合同编号:2019020900063),经费来源:辽宁省检验检测认证中心(辽宁省安全科学研究院),起止日期:2019年8月-2019年11月,4.8万,主持。

- (21) 2019年,中国航发沈阳发动机设计研究所(606所)两机专项外协项目(2019JX04H001),某B型发动机管路系统动力学特性分析及振动抑制研究,2019.6-2022.12,348万,主持。

- (20) 2019年,“兴辽英才计划”青年拔尖人才(XLYC1807008),辽宁省组织部,2019.1-2021.12,50万,主持。

- (19) 2019年,项目名称:变转速下滚动轴承非平稳振动信号分析及故障诊断研究 (项目编号:N180306005),经费来源:教育部项目基本科研业务费项目—博士生项目,起止年月:2019年1月-2020年12月,经费额度4.9万。

- (18) 2018年,项目名称:含叶片裂纹损伤的转子-盘片-机匣耦合系统碰摩动力学及机匣包容性研究(项目编号:N170306004),经费来源:教育部项目基本科研业务费项目—博士生项目,起止年月:2018年1月-2019年12月,经费额度3万。

- (17) 2018年,项目名称:航空发动机关键部件疲劳、振动预估及运行安全性控制(项目编号:N170308028),经费来源:教育部项目基本科研业务费项目—重大项目,起止年月:2018年1月-2020年12月,经费额度100万。

- (16) 2018年,项目名称:航空发动机双转子-支承-机匣耦合系统典型碰摩激振机理研究 (项目编号:11772089),经费来源:国家自然科学基金委,起止年月:2018年1月-2021年12月,直接经费额度62万。

- (15) 2017年,辽宁省高等学校创新人才支持计划 (LR2017035),辽宁省教育厅,2017.12-2019.12,10万,主持。

- (14) 2017年,与清华大学、西门子燃气轮机合作横向课题(2017020900024):基于ANSYS的燃气轮机叶片脱落对转子动力学特性影响研究", 2017.3-2018.12,20万,主持。

- (13) 2017年,项目名称:振动与噪声分析的新理论 (申请指南代码61402100102),经费来源:装备预研领域基金项目,起止年月:2017年12月-2019年12月,经费额度50万。

- (12) 2017年,项目名称:直升机主减速器齿轮系统动力学建模及振动响应预估 (项目编号:N160313004),经费来源:教育部项目基本科研业务费项目—国防预研项目,起止年月:2017年1月-2018年12月,经费额度 12万。

- (11) 2017年,项目名称:航空发动机转子-机匣耦合系统动力学及碰摩激振机理(项目编号:MSV201707),经费来源:“机械系统与振动”国家重点实验室,起止年月:2017年1月至2018年12月,经费额度10万。

- (10) 2016年,项目名称:基于模型的旋转叶片裂纹损伤定量诊断研究 (项目编号:N150305001),经费来源:教育部项目基本科研业务费项目优秀科技人才培育基金,起止年月:2016年1月-2017年12月,经费额度 30万。

- (9) 2015年,项目名称:旋转叶片裂纹损伤动力学建模及定量诊断研究(项目编号:SV2015-KF-08),经费来源:“机械结构强度与振动”国家重点实验室,起止年月:2015年11月至2017年10月,经费额度10万。

- (8) 2015年,项目名称:航空发动机旋转叶片-涂层机匣碰摩机理及动力学特性研究(项目编号:No. U1433109),经费来源:国家自然科学基金委与中国民用航空局联合资助项目,起止年月:2015年1月-2017年12月,经费额度38万。

- (7) 2014年,项目名称:旋转叶片-涂层机匣碰摩机理及动力学特性研究 (项目编号:N130403006),经费来源:教育部基本科研业务费,起止年月:2014年1月-2015年12月,经费额度 15万。

- (6) 2010年,国家重点实验室开放基金:齿轮耦合的压缩机转子系统动力学特性研究 (项目编号:SKLMT-KFKT-200903),经费来源:重庆大学机械传动国家重点实验室,起止年月:2010.1-2012.12.,经费额度 8万。

- (5) 2011年,教育部基金科研费项目:压气机叶片机匣碰摩机理及非线性动力学特性研究 (项目编号:N100403008),经费来源:教育部,起止年月:2011年1月-2012年12月,经费额度 8万。

- (4) 2011年,教育部新世纪优秀人才支持计划项目:叶片机匣碰摩机理及动力学特性研究(项目编号:NCET-11-0078);经费来源:教育部,起止年月:2011年1月-2014年12月;经费额度 50万。

- (3) 2009年,项目名称:大型离心压缩机损伤转子系统运动稳定性研究 (项目编号:20090450111),经费来源:中 国 博 士 后 科 学 基 金面上项目(一等),起止年月:2009.9-2011.9,经费额度 5万。

- (2) 2009年,教育部博士点基金项目(新教师):基于特征演变的大型离心压缩机转子系统耦合碰摩故障机理研究 (项目编号:200801451009),经费来源:教育部,起止年月:2009年1月-2011年12月,经费额度 3.6万。

- (1) 2009年,国家自然科学基金项目:大型离心压缩机转子系统的耦合碰摩故障机理若干关键问题的研究(项目编号:50805019),经费来源:国家自然科学基金委,起止年月:2009年1月-2011年12月,经费额度 22万。